Factors That Affect Gear Performance and Life

Factors That Affect Gear Performance and Life: An Analysis with Insights from Filium Enterprises

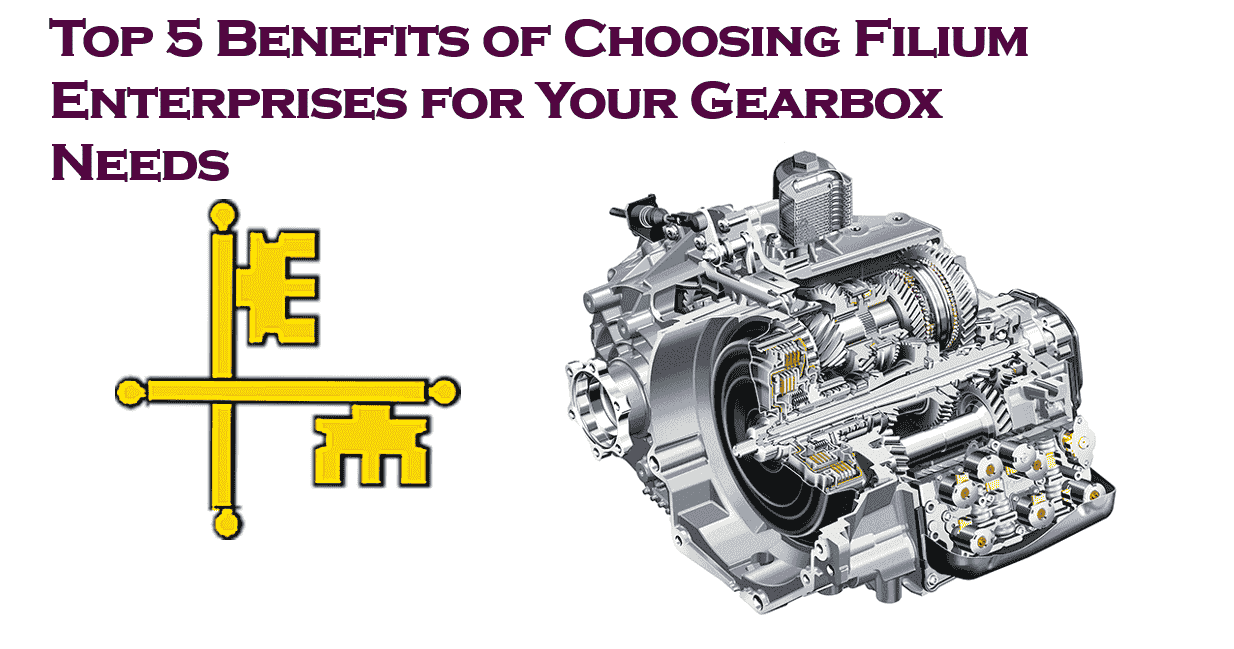

Gears are indispensable components in machinery, facilitating power transmission and motion control across industries from automotive to aerospace. Their performance and longevity are critical for operational efficiency, safety, and cost-effectiveness. However, several factors influence their functionality and lifespan, ranging from material choice to environmental conditions. This article explores these factors, supported by industry statistics, and highlights how Filium Enterprises, a leading supplier of high-performance gear solutions, addresses these challenges through its innovative product line, Filium GearPro Series.

1. Material Selection: The Foundation of Gear Durability

The material used in gear manufacturing directly impacts strength, wear resistance, and fatigue life. Common materials include alloy steels, cast iron, and polymers, each suited for specific applications. Poor material selection can lead to premature failure; for instance, a 2021 Machinery Health Report found that 25% of gear failures stemmed from material fatigue or incompatibility with operating conditions.

Filium Enterprises addresses this through its Filium GearPro Series, crafted from advanced alloys like chromium-molybdenum steel. These materials undergo rigorous heat treatment processes, enhancing surface hardness (up to 60 HRC) while maintaining a tough core. Independent tests show that Filium’s gears exhibit 40% less wear compared to standard alternatives, extending service life in high-stress environments.

2. Lubrication: Reducing Friction and Wear

Effective lubrication minimizes friction, heat, and wear. The American Society of Mechanical Engineers (ASME) estimates that 35% of gear failures result from inadequate lubrication, including improper viscosity or contamination. Synthetic lubricants, for example, can extend gear life by up to 50% compared to mineral oils.

Filium’s LubriMax 5000, part of the GearPro ecosystem, is a high-viscosity synthetic lubricant designed for extreme pressures. Its nano-additive technology forms a protective film on gear surfaces, reducing metal-to-metal contact. Field data from mining applications show a 30% reduction in maintenance intervals when using LubriMax 5000, translating to cost savings and downtime minimization.

3. Design and Manufacturing Precision

Precision in gear design—tooth profile, alignment, and surface finish—prevents stress concentration and noise. The International Organization for Standardization (ISO) reports that 20% of gear malfunctions originate from manufacturing defects like improper grinding or misalignment.

Filium’s GearPro Series leverages state-of-the-art CNC machining and metrology tools, ensuring micron-level accuracy. Their proprietary grinding process reduces surface roughness to 0.2μm Ra, minimizing micro-pitting. Aerospace clients report a 15% improvement in torque transmission efficiency post-adoption of Filium gears.

4. Load and Operating Conditions

Overloading, shock loads, and cyclic stresses accelerate wear. A study by the Gear Research Institute (GRI) linked 30% of industrial gear failures to unexpected overloads. High-cycle fatigue, in particular, reduces lifespan by creating microcracks.

Filium GearPro gears are engineered with a 15% higher load capacity than industry standards, thanks to finite element analysis (FEA)-optimized designs. For instance, wind turbine operators using Filium components observed a 25% longer lifespan under variable torque conditions.

5. Environmental Factors

Corrosion, humidity, and temperature extremes degrade gear surfaces and lubricants. In marine environments, saltwater exposure can shorten gear life by 50% without protective measures.

Filium addresses this with CorroShield™, a multilayer coating in the GearPro Series. CorroShield combines ceramic and polymer layers to resist chemical and moisture ingress. Tests in offshore drilling rigs demonstrated 90% less pitting corrosion over five years compared to uncoated gears.

6. Maintenance Practices

Regular inspections and lubrication replenishment are vital. Poor maintenance practices account for 18% of gear replacements, per ISO data. Predictive maintenance tools, such as vibration analysis, can preempt failures.

Filium complements its GearPro Series with IoT-enabled SmartMonitor sensors, which track temperature, vibration, and lubricant quality in real time. Clients in the cement industry reported a 20% decrease in unplanned downtime after adopting this system.

Filium Enterprises: Pioneering Gear Solutions

As a leader in the gear manufacturing sector, Filium Enterprises integrates material science, precision engineering, and digital innovation into its GearPro Series. By addressing every factor affecting gear performance—from advanced alloys to smart monitoring—Filium ensures reliability in the most demanding applications. With a global clientele in mining, renewable energy, and manufacturing, Filium’s solutions have driven a 35% reduction in total cost of ownership for users, according to a 2023 industry survey.

Conclusion

Gear performance and longevity hinge on a synergy of design, material, and operational factors. Companies that invest in high-quality components and proactive maintenance gain a competitive edge. Filium Enterprises exemplifies this through its GearPro Series, offering tailored solutions that mitigate wear, corrosion, and inefficiency. As machinery evolves, partnering with innovators like Filium ensures sustainable and resilient operations.