Filium TPE Product Line with TPV and more included

The Thermoplastic elastomer (TPE)

The thermoplastic elastomer (TPE) is similar to rubber, which is good for plastics processing. It is highly

elastic, environmentally friendly, non-toxic and safe. It does not need to be vulcanized, and it has

excellent coloring, weather resistance and other such properties. Its production process is simple and

cost down, and is recyclable. It can be molded with PP, PE, PC, PS, ABS or PA (Nylon) through

integration or separately.

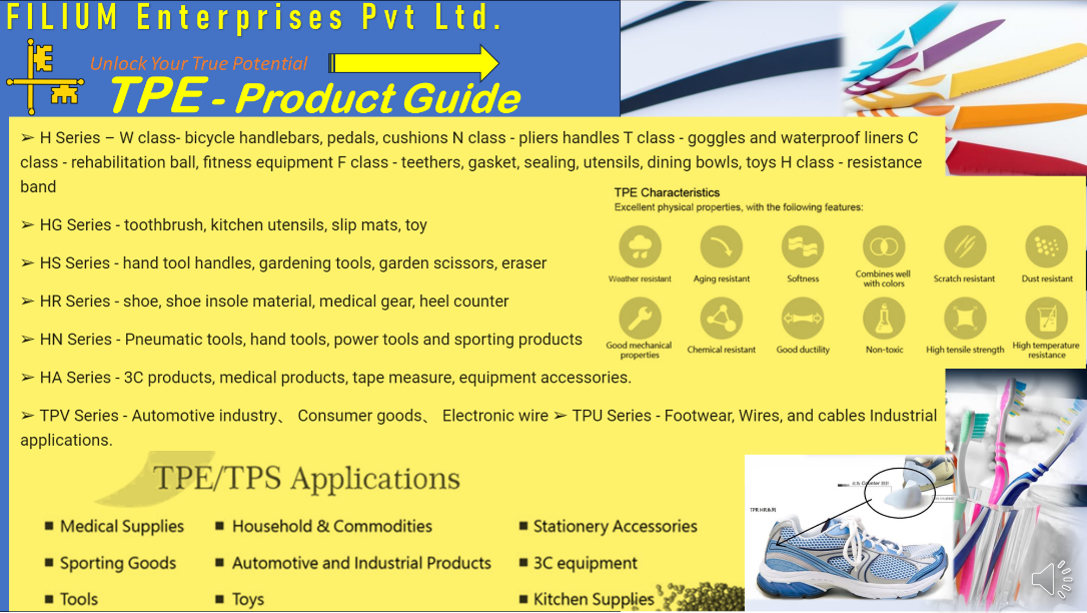

TPE Characteristics

Excellent physical properties, with the following features:

Combines well, Weather resistant, Aging resistant, Softness: Scratch resistant Dust resistant

with colors, Good mechanical, Chemical resistant, Good ductility, Non-toxic, High tensile strength, High temperature resistance

TPE/TPS Applications

Medical Supplies, Household & Commodities, Stationery Accessories, Sporting Goods, Automotive and Industrial Products, 3C equipment, Tools Toys, and Kitchen Supplies

Filium Material Based Custom and Specific Production

Our current consumer trends have been moving towards customized services, such as personalized computer mouse pads, personalized mugs and even personalized women perfume

scents. These customized items not only show a personal preference and taste, but also become characteristic of a particular group with certain items; such as machinery equipment or household furniture.

Except current stable and regular materials, FILIUM also would like to work with our clients to develop particular materials for product life cycles and market trends in the future.

Customized products! Customized professional services!

In these series of processes, FILIUM has specialists to check each step of the process! To establish and improve the process and quality inspection system, as well as to thoroughly review each of the development process and implement innovative ideas, we focus on the details in teamwork. With such an organized and integrated system, everyone well performed their duties while established thorough communication between different departments. These processes allow us to work closely and being pleasurable, which maintain our first priority to produce good particles!

Below is an introduction to a variety of F series materials. They can be used for customer requirements based on the chosen specifications.

F series has the privileged binding features when combining with hard plastic materials, and its soft texture with excellent physical properties could meet any functional design. It is

The F series is classed as the SEBS (STYRENE-ETHYLENE/BUTYLENE-TYRENE) hydrogenated grade family of materials.

F series has the privileged binding features when combining with hard plastic materials, and its soft texture with excellent physical properties could meet any functional design. It is

exceptional presentation in the consumer products market with satisfactory levels of aging resistance, weather resistance and scratch resistance.

+ The optimum combination of materials: PP/PE/EVA

+ Heat distortion temperature: 70°C

+ Cold resistance temperature: -40°C

Applications:

Food container seals, water filter washers, non-slip cutting board mats, goggles, hand tool handles, golf club handles, bicycle handles, toys, bracelets, pop bottle washers, all kinds of gaskets, medical supplies, protective gear jackets, sporting goods, yoga mats, retractable belts, flashlight accessories, anti-dust covers, packing straps, reinforced packing hangers, children dining bowls and utensils, teethers, ice cube trays, bottle openers, cup sets, bottle.

Material Class is divided into:

W Class:

The material is white and it can be easily dyed to any color with comfortable texture and durable to any

weather changes. It is often being the best choice for out-door and fitness supplies, because of its wear

resistance and flexibility, moreover, it is available in a wide array of bicycle handlebars, pedals,

cushions and various yoga related products.

N Class:

The material is translucent and light gravity, its good coloring and elastic properties which give the

product a cushioned feel and the broad range of hardness can reach SHORE 30A~ SHORE 60D. For example, the pliers handles, need to have a highly resilient force in using, it means that the user doesnt need to put much strength by hand. A full elasticity handle made of great specific materials, it not only makes the tool easier to use, but also gives it a more ergonomic design.

C Class:

This material is transparent with super soft, which is similar to the texture of skin. Its shockproof effect may reduce the impact of the crash to as touching the ground, particularly with bigger or bouncy actions. The outstanding shockproof features form the buffer and slow down the uncomfortable feeling by the impact. Since it has first-rate properties, this Class is used a lot in insoles and always becomes the best choice for footwear manufacturers.

T Class

The material is transparent, and follows with its stretching elasticity, like high permeability, tensile strength, and tear strength. It is environmentally safe and does not cause skin allergies or discomfort. With a hermetically sealing effect, this material is considerable to utilize in goggles and waterproof liners. Furthermore, the snorkel used to connect the oxygen tubes for diving equipment were also made by this class of material.

FF Class

The material is food grade as satisfactory to U.S. FDA regulations that made of translucent. The user may feel ease as it is a safe and non-toxic material that can replace PVC and latex materials. For example, the container seals keeping food in fresh over a long period of time and the anti-slippery mat for cutting board. In addition, the applications aiming at the baby market such as the shatterproof dining bowls and utensils, others like toys and teethers, etc.

H Class

The material is transparent with high physical properties, great cold resistance and good tear resistance. It is suitable for applications with extreme requirements, such as the straps, used in packaging, bundling and transport, which makes the products more secure on the packaging because of superior tensile strength. On the other items, such as chest fitness strap, that has the extraordinary resilient force and anti-aging to make the exercisers easily achieving the body-building

HG series

The HG series is classed as the SEBS (STYRENE-ETHYLENE/BUTYLENE-STYRENE) hydrogenated grade of materials

This series combines well with hard plastic materials and have the softness of the elastomers, therefore, it can serve both appearance and anti-scratch functions. When using this material, its functions can be altered by adding different formulations or additives based on product requirements, for instance, adding anti-mildew and antibacterial will make the product life longer.

The HG series is used in anti-slip pads/mats, business-type handles and a variety of toothbrushes. For ‘example, the functionality of the toothbrush was breaking the traditional style by using. The TPE /TPS material can be bonded on the grip and back of the brush head, besides, it also can be embedded in and be the bristle. All of which makes cleaning efficient! Thus, the HG series is always to be the best material for toothbrush.

W Class : White Color B Class : Black Color

+ Heat distortion temperature: 70°C

* Cold resistance temperature:-40°C

Applications: HG Series fruit knife | A HG Series toothbrush

All types of commercial handles, toys, gardening tools, sporting good parts, pedals (mats) , slip mats, anti-crash mats, fitness equipment, gaskets, medical equipment, toothbrushes, razors, kitchen utensils (ice cube trays, spatulas), coasters, cup sets, cleaning kits, ete.

HR Series

The HR series belongs to the SBS(STYRENE- BUTADIENE-STYRENE BLOCK COPOLYMER) non-hydrogenated grade of materials.

The HR series involving applications of footwear, mainly for abrasion resistance, softness, tear strength and other requirements. It has adhesive properties and is thus able to work closely with other materials; it provides the functions for any shoes those basic requirements are wear-resistant and tough Therefore, a good material made of elastic in scope of shoes, makes moving easier, that feels soft on the skin and comfortable for the legs to relieve fatigue!

Our HR series is used fairly extensively in shoe materials, for both the appearance and functionality of shoe accessories, heels, soles and insoles are mostly being with satisfied!

* The optimal combination of materials:

The HS series

The HS series belongs to SEBS (STYRENE-ETHYLENE/BUTYLENE-STYRENE) hydrogenated grade of materials.

This material can replace PVC, it is an economical type material with competitive ability. The physical properties can meet the economic aspects and the needs of clients by being anti-UV, anti-yellowing (discoloring), anti-mildew and antibacterial. After the molding, it has good flexibility and slip-resistant, it becomes dense and binds well, when it makes a dual colored material. Furthermore, the unique properties in its texture and overall appearance provide the product with value-added and anti-scratch features.

The HS series is commonly used in handles and gardening tools, such as sprinkler guns and garden scissors,

Applications: AHS Series erasers. AHS Series sprinkler gun

All kinds of economical type hand tool handles, flower scissor handles, scissor handles, toys,

gardening gun handles, seals, reels, fenders, sport good parts, medical instruments, erasers and other

stationery products.

The HN series

The HN series belongs to the SEBS (STYRENE-ETHYLENE/BUTYLENE-STYRENE) hydrogenated and alloyed grade of materials.

The HN series, it specialized in PA(Nylon) over-molding, has excellent weather resistance, heat

temperatures resistance on processing and extraordinary anti-scratch. The HN series texture is dry and comfortable; in addition to forming, the HN series always performs well in a double layer injection when bonds with PA6 and PA66 material

For example, when using pneumatic or power tools, nylon is required as the main material due to their

different characteristics and structure, however, in order to enhance a soft grip comfort and a sense of design, the material must not only be soft, but also have good binding properties.

Our HN series has overcome the problem of high temperatures injection and bonded- molded, its virtues develop the good performance in the field of pneumatic tools, power tools and sport products.

+ The optimum combination of materials: PA (Nylon)

+ Material Class: W Class - White Color Se

+ Heat distortion temperature: 100°C

* Cold resistance temperature: -50°C

Applications:

Sport goods, pneumatic tools, power tools, ete. “HN Series power tools

The HA series

The HA series belongs to the SEBS (STYRENE-ETHYLENE/BUTYLENE-STYRENE) hydrogenated and alloyed grade of materials.

The materials of the HA series are slip resistant, soft and comfortable, look good and has excellent mechanical strength and scratch resistance. It can be combined with ABS and PC materials with excellent shot sticky strength.

For example, the thermoplastic elastomer material (TPE/TPS) in coating on 3C product and medical product is a good choice with regards to both performance and value.

HA series can meet the needs of such commercialization, and it is the best choice for customers’

needs!

* The optimal combination of materials: ABS / PC

* Material Class: j

W Class: White Color

+ Heat distortion temperature: 100°C

* Cold resistance temperature: -50°C

Applications:

Sporting goods, knife accessories, 3C product accessories (such as: headphones, mice, flash drives, computers, etc.), medical supplies accessories (such as: blood glucose and blood pressure measuring equipment), tools, and equipment accessories (such as: multi-meter, tape measure, bar code machine.

The grades of TPU particles (resin) can be simply categorized into: injection grade, extrusion grade, and blowing grade. Some TPU material is molded by particles and some are made of varying thicknesses films for different product applications. TPU can be recycled, coloring, and has high processing efficiency.

TPU has been widely used in electronic appliances, the health care industry and footwear, because of easy processing, which itis suitable for extrusion molding and injection molding machines. However, TPU easily absorbs water, if moisture control is not thorough during processing, it will result in poor performance. So drying process is required before manufacturing.

TPU Hardness Range SHORE 70 A to SHORE 60D

TPU material applications:

1. Footwear: baseball shoes, golf shoes, soccer shoes, shoe soles and forefoot insert insoles, heels, boots, safety boots, etc.

2. Supplies: handles, straps, sealing strips.

3. Industrial: anti-shock components, bushings, bearings, hoses, high pressure pipes, medical tubes, pipes, fuel pipes, anti-dust covers, etc.

4. Wires and cables: computer wiring, automotive cables.

TPV

TPV material does not need to be vulcanized in the process, it is easy to process with good performance and coloring, and it has natural rubber advantages of elasticity and durability, and can be combined with PP + PE » EVA or other materials for injection molding, blowing molding and extrusion molding machine in processing. This material is recyclable and environmentally friendly.

+ TPV hardness range: SHORE 25 A ~ SHORE 60 D

Various TPV Applications:

1. Automotive industry: automotive seals, anti-dust covers, bumpers, fenders, etc.

2. Consumer goods: hand tools, power tools, medical appliances, bathroom supplies and types of

packaging.

3. Electronic wire: insulating sleeves, wires and cables 4, Industrial: all kinds of sealing strips.

Hope this was informational, for further details please contact us via our central chat application located at our home page, or WhatsApp our central Customer Support at +916399080727 for quotes for material and custom product prototyping and production. You can also submit the RFQ under the Bulk Pricing link with your product design and details, or email us at Services@filiumenter.com