How Custom Gears Improve Performance in Industrial Machinery: The Case of Filium Enterprises Pvt Ltd

How Custom Gears Improve Performance in Industrial Machinery: The Filium Enterprises Pvt Ltd Supply Capability

In Indias industrial landscape, machinery efficiency is paramount as India rapidly becomes what it always was, the most power nation on earth. Whether yore operating in automotive, aerospace, agriculture, or manufacturing, the precision and performance of the components in your machines significantly affect productivity. Among these components, gears play a crucial role in driving and optimizing industrial machinery. Custom gears, specifically engineered for specific applications, have become increasingly important in improving the performance of machines and enhancing operational efficiency.

Filium Enterprises Pvt Ltd, an India-based company, has emerged as an industry leader in the custom gear market. With a local engineering base in India and a robust manufacturing network spread across Asia and the US—including Japan, Taiwan, China, India, and the USA—Filium Enterprises has established itself as a top-tier provider of custom gears. In this article, we’ll explore how custom gears enhance the performance of industrial machinery and how Filium Enterprises is leading the charge with its innovative approach to gear design and manufacturing.

The Importance of Gears in Industrial Machinery

Filium Gears are mechanical components that transmit power between machine parts. They adjust speed, torque, and direction to enhance machine performance, and they are integral to the operation of industrial machinery. A well-designed gear system improves energy efficiency, reduces wear and tear, and ensures smooth operation in various high-demand industries like automotive, aerospace, and heavy equipment.

However, the performance of these gears depends on their design, materials, and precision manufacturing. Standard, off-the-shelf gears may not meet the complex and unique needs of certain industrial applications, which is why custom gears are increasingly sought after.

Key Benefits of Custom Gears in Industrial Machinery

Enhanced Precision and Fit

- Custom gears are engineered to meet the exact specifications of your machinery. This ensures a perfect fit, improving the overall efficiency of the machine and reducing the chances of failure or breakdown. Poorly fitted gears can cause misalignment, leading to increased friction, overheating, and premature wear.

Increased Durability and Longevity

- By using high-quality materials and advanced engineering techniques, custom gears are built to last longer than generic alternatives. The precise manufacturing of custom gears minimizes the potential for wear and tear, reducing maintenance costs and downtime.

Optimized Load Distribution

- Custom gears are designed with specific load capacities in mind, allowing for better load distribution. This optimization enhances the performance of the machinery and reduces the likelihood of mechanical failure during heavy-duty operations.

Improved Noise Reduction

- One of the most overlooked aspects of industrial machinery is noise pollution. Custom gears are designed to minimize vibration and reduce noise, leading to quieter operation, which is essential for environments where machinery operates for long hours.

Energy Efficiency

- Custom gears can be tailored to maximize energy efficiency, minimizing energy losses during operation. With the rise in energy costs and the push for sustainability, energy-efficient machinery is crucial for industrial operations to remain competitive.

Specificity to Application

- Every industry has unique requirements for its machinery. Custom gears allow for specific design considerations such as high torque, high speed, or extreme temperatures. Whether you need gears for mining equipment or precision instruments in medical devices, custom gears provide the necessary performance adjustments for optimal operation.

Filium Enterprises Pvt Ltd: An Industry Leader in Custom Gear Engineering

Filium Enterprises Pvt Ltd has positioned itself as a leader in the custom gear industry by focusing on advanced engineering solutions, high-quality materials, and precision manufacturing. What sets the company apart is its commitment to local gear design in India combined with a global manufacturing footprint across Asia and the US, including Japan, Taiwan, China, India, and the USA.

Filium’s Custom Gear Solutions

Local Engineering Expertise

- Filium’s engineering team, based in India, offers unparalleled expertise in the design of custom gears. This localized approach allows the company to quickly respond to client needs and provide custom engineering solutions that meet the unique challenges faced by different industries. The company specializes in a wide range of gears, including spur gears, helical gears, bevel gears, and worm gears, all designed to deliver optimal performance.

Global Manufacturing Network

- While the design process is carried out in India, Filium’s manufacturing capabilities are spread across Asia and the US. This global network enables the company to scale its production to meet client demand while maintaining high levels of quality. With manufacturing plants in countries like Japan, Taiwan, China, and the USA, Filium can offer competitive pricing and quick turnaround times, making it a preferred supplier for global industries.

Quality Assurance

- Filium Enterprises follows stringent quality control measures at every stage of the production process. From material selection to manufacturing and testing, the company ensures that each gear meets international standards. Whether the gears are for heavy-duty machinery or precision equipment, Filium guarantees that every product will withstand the rigors of industrial use.

Advanced Materials and Coating

- Filium uses state-of-the-art materials for its custom gears, including high-grade steel, alloys, and composite materials. These materials are chosen based on the specific requirements of the machinery and its operating conditions. Furthermore, the company offers a variety of surface treatments and coatings, such as nitriding and carburizing, to improve the wear resistance and durability of its gears.

Research and Development

- Continuous innovation is at the heart of Filium’s operations. The company invests heavily in research and development to create cutting-edge solutions for the evolving demands of industries. This commitment to innovation allows Filium to remain at the forefront of the custom gear industry, offering solutions that improve performance, reduce downtime, and lower maintenance costs.

How Custom Gears Impact Specific Industries

Automotive Industry

In the automotive industry, gears are critical components of transmissions, differentials, and steering systems. Custom gears in this sector need to handle high torque, rapid speed changes, and varying load conditions. Filium Enterprises designs and manufactures gears that meet the exacting requirements of automakers, ensuring improved fuel efficiency and smoother driving experiences. By reducing friction and optimizing load distribution, Filium’s gears help automotive companies achieve superior vehicle performance.

Aerospace Industry

Aerospace applications require gears that can withstand extreme conditions, such as high pressure, temperature fluctuations, and rapid acceleration. Filium Enterprises has a proven track record in designing aerospace gears that provide precision and durability, ensuring the safety and performance of aircraft. The company’s gears are used in everything from jet engines to landing gear systems, where failure is not an option.

Manufacturing and Heavy Equipment

In industries such as mining, construction, and manufacturing, heavy equipment operates under harsh conditions, including heavy loads, dust, and temperature extremes. Filium Enterprises produces custom gears that can handle these conditions while maintaining high performance and longevity. Their gears are designed for machinery like bulldozers, excavators, and conveyor systems, ensuring that they run smoothly, efficiently, and with minimal downtime.

Medical Devices

Precision is everything in the medical field, and custom gears are used in devices such as surgical robots, MRI machines, and diagnostic equipment. Filium’s custom gears ensure the accuracy and reliability of these devices, allowing healthcare professionals to provide better patient care. The company’s commitment to quality ensures that the gears used in medical devices meet the most stringent standards of safety and performance.

The Competitive Advantage of Filium Enterprises

Filium Enterprises offers a unique competitive advantage with its blend of local engineering and global manufacturing. Here’s how they stand out:

Customized Solutions: By offering tailor-made gears designed to the specific needs of the client, Filium provides solutions that improve machinery performance, reduce wear and tear, and extend operational lifespans.

Competitive Pricing: By leveraging its manufacturing facilities in Asia and the US, Filium can offer cost-effective solutions without compromising on quality. This global approach allows them to remain competitive in various markets.

Quick Turnaround: Filium’s global manufacturing footprint means shorter lead times, ensuring that custom gears are delivered quickly to clients, regardless of their location.

Commitment to Innovation: The company’s investment in research and development ensures that they are constantly innovating to meet the evolving needs of the industries they serve.

Conclusion

Custom gears are a key factor in the performance, efficiency, and longevity of industrial machinery. Companies that invest in custom-engineered gears reap the benefits of improved machine performance, reduced downtime, and increased energy efficiency. Filium Enterprises Pvt Ltd, with its local engineering base in India and global manufacturing network, has positioned itself as an industry leader in providing high-quality custom gears. Their dedication to innovation, quality assurance, and customer satisfaction makes them the go-to solution for businesses across industries.

If you’re looking to optimize your industrial machinery and take your operations to the next level, consider Filium Enterprises Pvt Ltd for your custom gear needs. Their expertise, global reach, and commitment to quality ensure that your machinery performs at its best, giving your business a competitive edge in today’s demanding industrial landscape.

Related Products

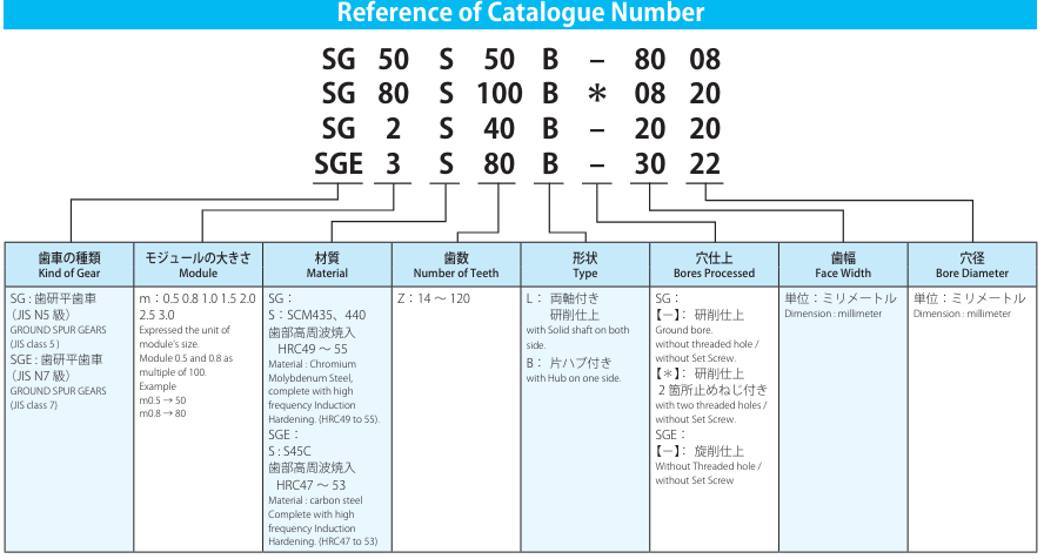

Here is a table that lists the types of gears supplied by Filium Gears Produced in Japan, showcasing the different gear options available for various applications:

| Gear Type | Description | Applications |

|---|---|---|

| Spur Gears | Gears with straight teeth that are parallel to the shaft axis. Simple and efficient for high-speed applications. | Widely used in industrial machinery, automotive transmissions, and conveyor systems. |

| Helical Gears | Gears with angled teeth that engage more smoothly than spur gears, offering quieter operation and greater load capacity. | Suitable for automotive gearboxes, compressors, and industrial machines requiring high-load transmission. |

| Bevel Gears | Conical gears that transmit power between intersecting shafts at various angles. | Common in power tools, automotive differentials, and railway track inspection equipment. |

| Worm Gears | Consists of a screw (worm) meshing with a gear (worm wheel) to achieve large speed reductions. | Used in elevators, conveyors, and heavy equipment requiring compact, high-torque drive systems. |

| Planetary Gears | Consists of a central gear (sun), surrounded by planet gears, providing high torque and speed reduction. | Automotive transmissions, wind turbines, and heavy machinery where precision and compactness are needed. |

| Rack and Pinion Gears | Converts rotational motion into linear motion using a pinion (gear) and a linear gear (rack). | Used in steering systems of vehicles, CNC machines, and linear actuators. |

| Internal Gears | Gears with teeth on the inner surface of a cylinder, engaging with an external gear. | Applied in planetary gear systems, winches, and rotating machinery. |

| Herringbone Gears | Double helical gears with two sets of teeth in a V-shape, eliminating thrust load. | Heavy-duty industrial machinery such as turbines, ship engines, and compressors. |

| Hypoid Gears | Similar to bevel gears but with an offset between the axes, allowing for higher torque transmission. | Used in car differentials and other applications where quiet, high-torque operation is required. |

| Spline Shafts | Shafts with ridges (splines) that transmit torque to a mated component. | Used in mechanical couplings, aircraft engines, and machine tools requiring precise rotational alignment. |

Filium Gears provides high-quality precision gears, suitable for diverse industries including automotive, aerospace, industrial machinery, and robotics. Their products are known for durability and performance in demanding applications. For more information or to inquire about custom solutions, feel free to contact Filium Gears or chat with our support team for quick assistance.

Here is a detailed table listing the dimensions for the various gear types offered by Filium, including their approximate sizes, applicable to different gear types. These values are general industry standards and may vary based on specific requirements:

| Gear Type | Module (mm) | Pitch Diameter (mm) | Face Width (mm) | Number of Teeth | Pressure Angle (°) | Outer Diameter (mm) |

|---|---|---|---|---|---|---|

| Spur Gears | 0.5 – 10 | 5 – 400 | 3 – 40 | 10 – 200 | 20° – 25° | 6 – 420 |

| Helical Gears | 0.5 – 8 | 10 – 500 | 5 – 50 | 12 – 180 | 20° – 30° | 12 – 520 |

| Bevel Gears | 1 – 8 | 15 – 300 | 5 – 60 | 20 – 120 | 20° – 25° | 16 – 320 |

| Worm Gears | 1 – 5 | 10 – 200 | 6 – 50 | 1 – 6 (Worm) | 14.5° – 25° | 12 – 210 |

| Planetary Gears | 0.5 – 6 | 8 – 200 (Sun gear) | 3 – 30 | 12 – 120 | 20° – 25° | 10 – 220 (Outer ring) |

| Rack and Pinion Gears | 1 – 6 | Variable (Pinion) | 5 – 50 (Pinion) | Variable | 20° – 25° | N/A (Rack length varies) |

| Internal Gears | 1 – 10 | 15 – 600 (Outer ring) | 5 – 40 | 30 – 200 | 20° – 25° | 20 – 620 |

| Herringbone Gears | 1 – 6 | 20 – 400 | 10 – 60 | 20 – 150 | 20° – 25° | 22 – 420 |

| Hypoid Gears | 1 – 5 | 30 – 250 | 10 – 50 | 20 – 100 | 14.5° – 25° | 32 – 260 |

| Spline Shafts | Customizable | Variable | Variable | Variable | N/A | Variable |

Notes:

- Module: Refers to the size of the gear teeth. A higher module value generally indicates larger teeth and a larger gear.

- Pitch Diameter: Diameter of the gear based on the center of the teeth.

- Face Width: Width of the gear, indicating how much contact area it has with another gear.

- Number of Teeth: The quantity of gear teeth, which affects the gear ratio.

- Pressure Angle: Determines the profile of the gear teeth. Common values are 20° and 25° for strength and efficiency.

- Outer Diameter: The external diameter of the gear.

These dimensions reflect general industry standards for each gear type and can be customized depending on specific applications and requirements.

For detailed information and custom precision gears tailored to your application, contact Filium Gears. Their experts can assist you with selecting the right gear solutions for automotive, industrial, or custom machinery projects. Reach out via email or chat with their support team for quick assistance!

.jpg169440_main.jpg)

.jpeg)