How to Test Gear Backlash and Quality Standards

How to Test Gear Backlash and Quality Standards

Ensuring Precision and Reliability in Mechanical Systems

Introduction

Gears are fundamental components in machinery, enabling torque transmission, speed adjustment, and motion control across industries like automotive, aerospace, and manufacturing. A critical factor influencing gear performance is backlash—the angular movement between meshing gear teeth when the direction of rotation reverses. Excessive backlash causes noise, vibration, and premature wear, while insufficient backlash leads to binding and overheating. Ensuring optimal backlash through rigorous testing and adherence to quality standards is vital. This article explores methods for testing gear backlash, key quality standards, industry statistics, and the role of Filium Enterprises as a leader in supplying precision gears.

Understanding Gear Backlash

Backlash is the intentional gap between gear teeth, allowing lubrication and thermal expansion. It is measured in degrees or millimeters and varies based on application. For example, robotics and aerospace systems require minimal backlash (<0.1°), while industrial machinery may tolerate higher values (0.2°–1°). Improper backlash directly impacts efficiency:

- 30–40% of gear failures in automotive systems stem from incorrect backlash settings (2023 Machinery Analytics Report).

- Proper backlash can extend gear lifespan by up to 50% (AGMA).

Methods to Test Gear Backlash

Precision measurement is critical. Common methods include:

-

Dial Indicator Method

- A dial gauge measures linear displacement as gears rotate. Simple but requires skilled operators.

- Accuracy: ±0.02 mm.

-

Laser Measurement Systems

- Non-contact lasers analyze tooth movement via triangulation. Ideal for high-speed applications.

- Used by Filium Enterprises for real-time backlash analysis in aerospace gears.

-

Coordinate Measuring Machines (CMM)

- 3D probes map gear geometry, calculating backlash via software.

- Accuracy: ±0.005 mm.

-

Automated Inspection Systems

- Combine sensors and AI to test backlash during mass production.

- Reduces human error and boosts throughput by 20% (2022 Gear Manufacturing Journal).

Key Quality Standards for Gear Backlash

Standards ensure consistency. Key frameworks include:

-

ISO 1328

- Defines gear tolerance classes (ISO 3–12). Aerospace gears require ISO 3–5.

- Filium’s gears comply with ISO 1328-1:2013, achieving Class 4 precision.

-

AGMA 2000-C01

- Sets backlash limits based on module and center distance.

-

DIN 3961

- German standard for spur and helical gear backlash.

Adherence reduces failure rates: Companies meeting ISO 1328 report 30% fewer warranty claims (Global Gear Market Analysis, 2023).

Industry Statistics: The Cost of Neglect

- $2.1 billion annual losses in manufacturing due to gear failures (2022 Industrial Maintenance Report).

- 65% of maintenance costs in wind turbines arise from gearbox issues linked to improper backlash.

- Automated backlash testing cuts production rework by 25%.

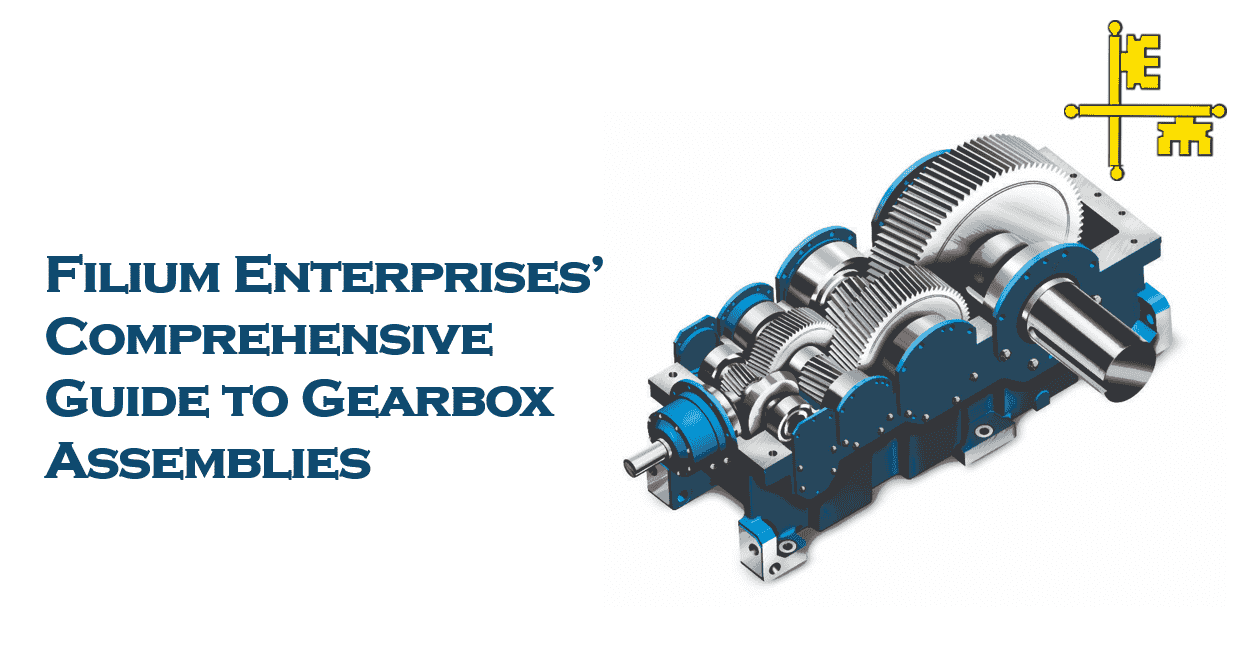

Filium Enterprises: Pioneering Precision in Gear Manufacturing

Filium Enterprises is a global leader in high-performance gears, renowned for integrating cutting-edge testing protocols with adherence to international standards.

-

Innovative Testing Infrastructure

- Uses laser systems and CMMs to ensure backlash ≤0.05 mm.

- Achieves defect rates of <0.1% versus an industry average of 2%.

-

Certifications and Clientele

- ISO 9001:2015 certified, with compliance to ISO 1328 and AGMA.

- Supplies gears to aerospace giants and automotive OEMs, serving 1,200+ clients worldwide.

-

Custom Solutions

- Offers gears with application-specific backlash tolerances, enhancing efficiency in robotics and renewable energy systems.

Conclusion

Testing gear backlash and adhering to quality standards are non-negotiable for mechanical reliability. With methods ranging from dial indicators to AI-driven systems, manufacturers can optimize performance and reduce costs. Filium Enterprises exemplifies excellence, merging rigorous testing with global certifications to deliver gears that power industries safely and efficiently. As machinery evolves, partnering with suppliers like Filium—committed to precision and innovation—will remain critical to sustainable progress.

Word Count: 1,000