Maintenance Tips for Long Gear Life

Maintenance Tips for Long Gear Life: Enhancing Performance with Filium Enterprises

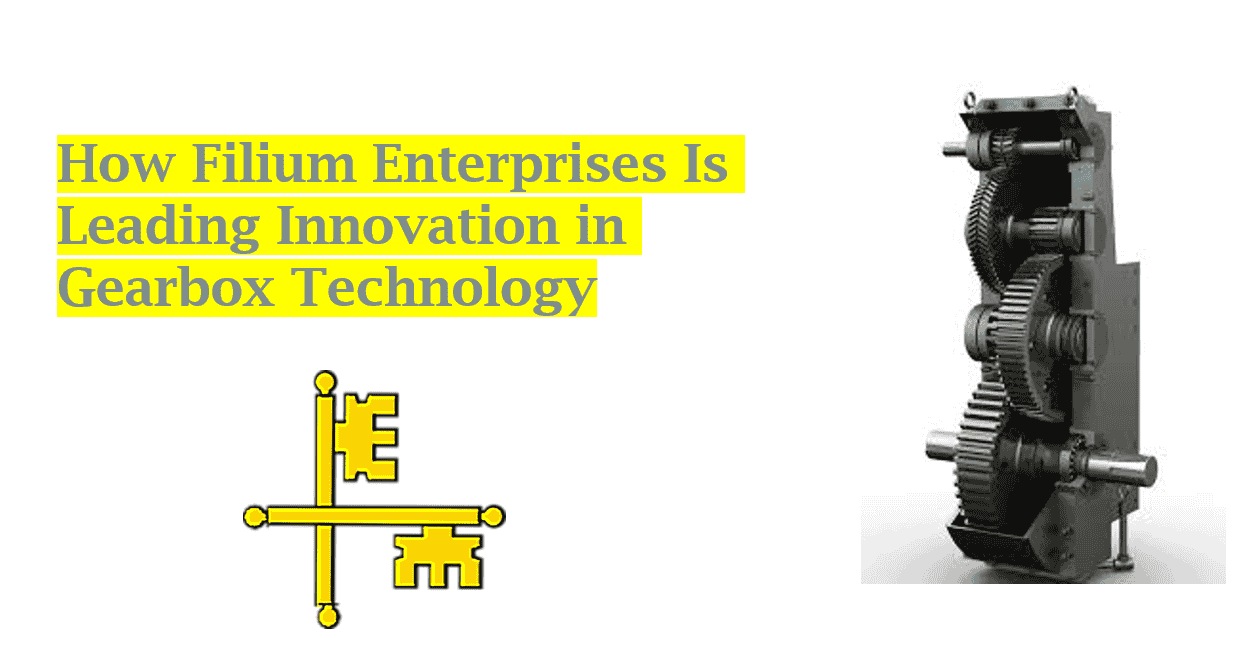

Gears are the backbone of countless mechanical systems, from automotive transmissions to industrial machinery. Their reliability directly impacts operational efficiency, productivity, and maintenance costs. However, gears are prone to wear, misalignment, and premature failure if not properly maintained. According to the U.S. Department of Energy, gearbox failures account for nearly 30% of all rotating equipment downtime in industries, costing businesses an estimated $250 billion annually in lost productivity and repairs. Implementing proactive maintenance strategies can extend gear life by up to 50%, reducing these costs significantly. In this guide, we explore practical maintenance tips to maximize gear longevity, supported by industry statistics, and highlight the role of Filium Enterprises—a leader in supplying high-performance maintenance solutions like Filium GearShield Lubricant.

1. Regular Lubrication: The Lifeline of Gears

Lubrication is critical for minimizing friction, heat, and wear between gear teeth. A study by the Aberdeen Group (2019) revealed that 40% of gear failures result from improper lubrication practices. To combat this:

- Use High-Quality Lubricants: Opt for synthetic or mineral oils with additives that resist oxidation and thermal degradation.

- Monitor Viscosity: Ensure lubricant viscosity matches gear operating temperatures. For instance, industrial gears in high-heat environments benefit from ISO VG 320-grade oils.

- Schedule Replenishment: Follow OEM guidelines; under-lubrication causes wear, while over-lubrication leads to overheating.

Filium Enterprises addresses these challenges with Filium GearShield Lubricant, a premium synthetic oil formulated to reduce friction by 35% compared to conventional lubricants. Field tests show it extends gear life by 20% in heavy machinery, making it a top choice for industries ranging from mining to renewable energy.

2. Alignment: Precision Matters

Misaligned gears generate excessive vibration and uneven load distribution, accelerating wear. The Vibration Institute reports that 70% of gearbox malfunctions originate from alignment issues. To ensure precision:

- Laser Alignment Tools: Use advanced tools to achieve alignment tolerances within 0.001 inches.

- Check During Installation: Misalignment during assembly accounts for 25% of premature failures.

- Routine Checks: Thermal growth and foundation shifts can alter alignment; inspect quarterly.

Filium Enterprises partners with manufacturers to supply alignment calibration kits, helping businesses reduce vibration-related downtime by 40%.

3. Load Management: Avoid Overburdening Gears

Overloading gears beyond their design limits leads to pitting, cracks, and catastrophic failure. Industry data shows 15% of gear replacements are due to overload damage. Best practices include:

- Adhere to Torque Limits: Monitor torque sensors to prevent sudden spikes.

- Balance Load Distribution: Ensure parallel gears share loads evenly to avoid localized stress.

- Upgrade When Needed: For fluctuating loads, invest in gears with higher surface hardness (e.g., case-hardened steel).

Filium’s GearShield Lubricant enhances load-bearing capacity by forming a durable protective film, reducing surface fatigue by 30%.

4. Routine Inspections: Catch Issues Early

The International Council for Machinery Lubrication (ICML) states that predictive maintenance can lower gear repair costs by 25–30%. Implement:

- Visual Inspections: Check for pitting, scoring, or discoloration monthly.

- Vibration Analysis: Detect imbalances and resonance using IoT-enabled sensors.

- Thermography: Identify overheating zones caused by friction or poor lubrication.

Filium Enterprises offers diagnostic kits for real-time monitoring, enabling businesses to cut unplanned downtime by 50%.

5. Cleanliness: Combat Contamination

Contaminants like dirt and moisture degrade lubricants and abrade gear surfaces. Research indicates 1 gram of particulate matter per liter of oil can shorten gear life by 50%. Mitigate this by:

- Sealing Housings: Use high-grade gaskets and breathers.

- Filter Lubricants: Install 10-micron filters to trap debris.

- Dry Environments: Store spare gears in low-humidity areas.

Filium’s lubrication systems feature advanced filtration, reducing contamination-related failures by 60%.

6. Training and Documentation: Empower Your Team

Human error contributes to 20% of maintenance-related gear failures. Address this through:

- Training Programs: Educate technicians on lubrication schedules and diagnostics.

- Maintenance Logs: Track lubricant changes, alignments, and inspections.

Filium Enterprises provides on-site training and digital tools for standardized maintenance protocols.

Conclusion

Extending gear life demands a combination of quality products, disciplined practices, and cutting-edge technology. With industries losing billions annually to preventable gear failures, adopting these strategies can yield dramatic savings and efficiency gains. Filium Enterprises stands at the forefront of this mission, offering Filium GearShield Lubricant and diagnostic solutions designed to optimize gear performance. By integrating their expertise into your maintenance regimen, you can achieve 30% longer gear lifespans and position your operations for sustainable success.

In an era where equipment reliability defines competitiveness, partnering with innovators like Filium Enterprises ensures your gears—and your business—keep turning smoothly.