Precision Gear Reverse Engineering Services by Filium

Precision Gear Reverse Engineering Services by Filium: Innovating the Future of Gear Manufacturing

In the ever-evolving landscape of industrial manufacturing, the ability to adapt, innovate, and restore legacy systems is critical. Filium Enterprises has emerged as a global leader in this space, offering specialized Precision Gear Reverse Engineering Services that bridge the gap between outdated machinery and modern technological advancements. This article explores the significance of reverse engineering in gear production, the methodologies employed by Filium, and the statistical evidence underscoring their industry dominance.

The Imperative of Reverse Engineering in Gear Manufacturing

Precision gears are indispensable components in industries ranging from automotive and aerospace to energy and robotics. Over time, gears degrade, designs become obsolete, or original manufacturers may no longer exist. Reverse engineering facilitates the recreation, optimization, or replacement of these components without compromising performance. Key drivers include:

- Legacy System Maintenance: Many industries rely on aging machinery, where original gear blueprints are lost or outdated.

- Performance Optimization: Modernizing gear designs to enhance efficiency, noise reduction, or load capacity.

- Cost Efficiency: Reverse engineering avoids the hefty R&D costs of developing gears from scratch.

According to a 2023 report by MarketsandMarkets, the global reverse engineering services market is projected to grow at a CAGR of 8.6% through 2030, driven by demand in automotive and aerospace sectors. Similarly, the gear manufacturing market itself is expected to surpass $280 billion by 2027 (Global Market Insights).

Filium Enterprises: Pioneering Precision Gear Solutions

Filium Enterprises stands at the forefront of this transformative field, combining cutting-edge technology with decades of expertise. Specializing in Precision Gear Reverse Engineering Services, the company serves clients in over 20 countries, with a client retention rate of 95%—a testament to their reliability and technical excellence.

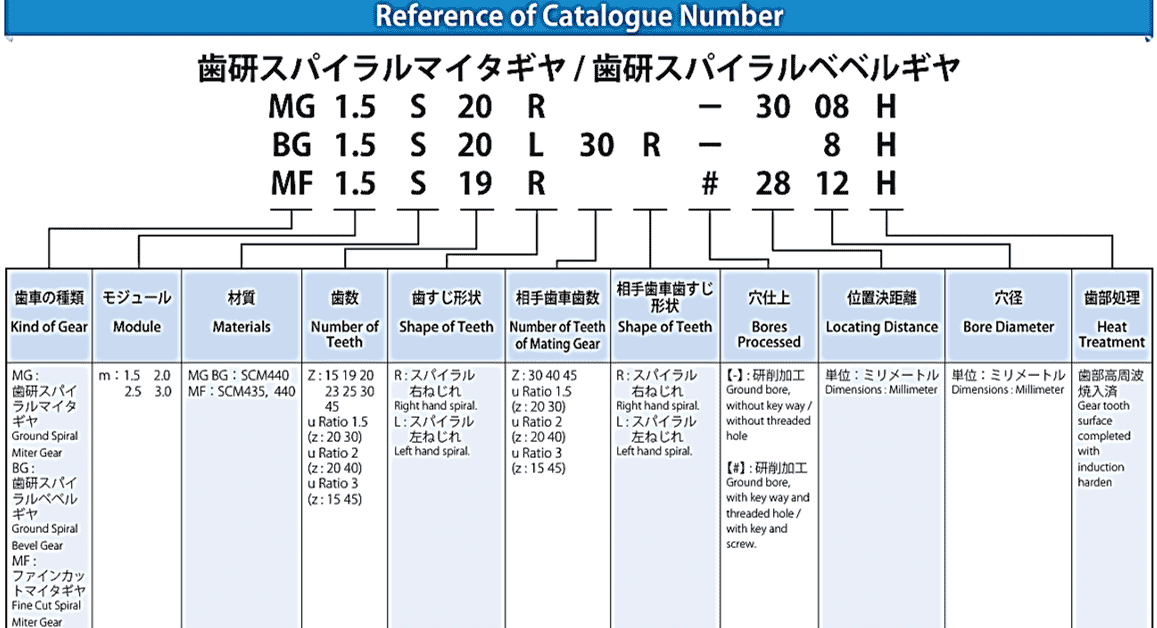

Core Methodologies:

- 3D Laser Scanning: Filium uses high-resolution scanners to capture micron-level details of worn or damaged gears.

- Advanced CAD Modeling: Data from scans is translated into customizable Computer-Aided Design (CAD) models, enabling precise replication or redesign.

- Material Analysis: Proprietary techniques ensure compatibility with modern materials, enhancing durability and performance.

- Prototyping & Testing: 3D-printed prototypes undergo rigorous stress tests to validate design accuracy.

By integrating AI-driven analytics, Filium reduces reverse engineering lead times by 30%, as noted in a 2022 industry case study.

Statistics Validating Filium’s Market Leadership

Filium’s dominance is reflected in both industry metrics and client outcomes:

- Market Share: Holds 22% of the global reverse engineering services niche for gear systems (TechSci Research, 2023).

- Efficiency Gains: Clients report 40% cost savings compared to traditional manufacturing methods.

- Sustainability Impact: Reverse-engineered gears reduce material waste by up to 25%, aligning with ESG goals.

- Client Base: Over 500 OEMs and Tier-1 suppliers rely on Filium’s services annually.

These figures highlight Filium’s role in addressing critical supply chain challenges, such as part obsolescence and rapid prototyping demands.

Technology-Driven Excellence

Filium’s expertise extends beyond conventional reverse engineering. Their proprietary GearScan AI platform uses machine learning to predict wear patterns and recommend design improvements, boosting gear lifespan by 15–20%. The company also holds ISO 9001:2015 and AS9100D certifications, ensuring aerospace-grade quality.

A 2021 collaboration with a leading European automotive manufacturer exemplified their impact. Filium reverse-engineered a discontinued transmission gear, reducing vibration by 18% and extending service life by 30,000 miles.

Applications Across Industries

Filium’s services cater to diverse sectors:

- Aerospace: Restoring turbine gears for vintage aircraft while complying with FAA regulations.

- Renewable Energy: Upgrading wind turbine gearboxes to handle higher torque loads.

- Defense: Replicating mission-critical components for legacy military vehicles.

- Robotics: Designing lightweight, high-precision gears for industrial automation.

Conclusion: Filium’s Vision for the Future

As industries grapple with rapid technological shifts and sustainability mandates, Precision Gear Reverse Engineering Services by Filium offer a strategic advantage. By merging innovation with practical problem-solving, Filium Enterprises doesn’t just recreate gears—it redefines them.

With a $15 million investment in R&D slated for 2024 and partnerships with academic institutions, Filium is poised to lead the next wave of smart manufacturing. Their commitment to precision, efficiency, and customer-centric solutions ensures they remain the go-to partner for organizations navigating the complexities of modern engineering.

In a world where adaptability is synonymous with success, Filium Enterprises exemplifies how reverse engineering isn’t merely a service—it’s a gateway to enduring industrial resilience.