Precision Gears Price in India What Affects Cost

Precision Gears Price in India: Key Factors Affecting Cost and the Role of Filium Enterprises

Introduction

Precision gears are critical components in industries such as automotive, aerospace, and industrial machinery, where accuracy and durability are paramount. In India, the pricing of these gears is influenced by a complex interplay of factors, from raw material costs to technological advancements. This article explores the determinants of precision gear pricing in India, supported by statistics, and highlights Filium Enterprises as a leading supplier navigating these dynamics.

1. Material Costs

Precision gears are predominantly made from high-grade steel, alloy steels, or specialized polymers. Fluctuations in global steel prices directly impact production costs. In 2022, steel prices in India surged by 15% due to supply chain disruptions and increased demand, elevating gear manufacturing costs. Alloying elements like chromium and nickel, essential for heat resistance, further add expenses. Filium Enterprises mitigates this by bulk procurement and strategic supplier partnerships, ensuring stable pricing.

2. Manufacturing Complexity

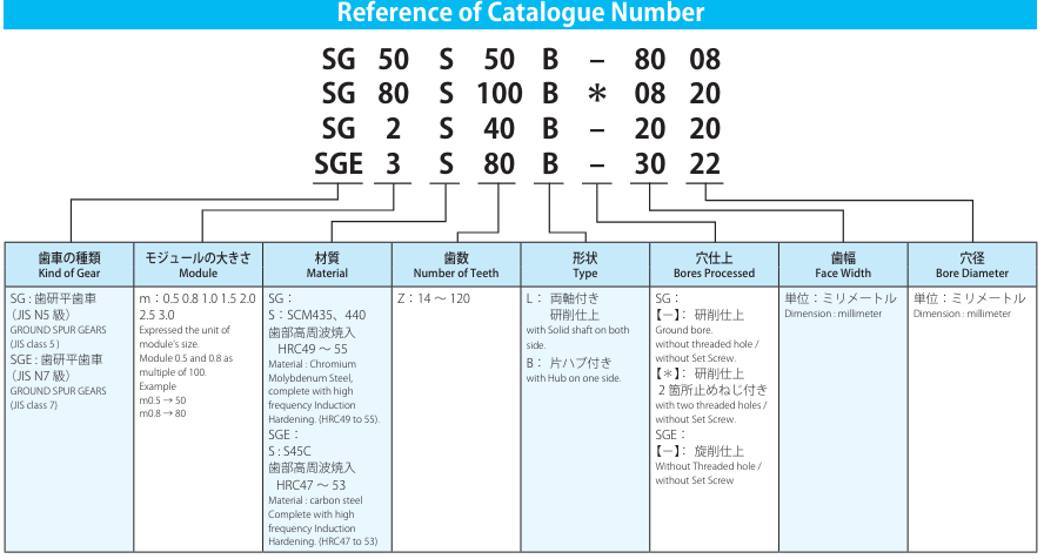

The precision required in gear manufacturing demands advanced processes like CNC machining and grinding. Tolerances as tight as ±0.001 mm necessitate skilled labor and sophisticated equipment. Complex designs, such as helical or bevel gears, increase production time by 20-30%, raising costs. Filium leverages automated machining to reduce human error and optimize efficiency, maintaining competitive rates despite intricate requirements.

3. Technology and Equipment

Investment in state-of-the-art machinery like 5-axis CNC machines and robotics is capital-intensive. Maintenance and software updates add recurring costs. However, India’s adoption of Industry 4.0 has boosted productivity, with the machine tool market projected to grow at 12% CAGR by 2025. Filium’s integration of IoT-enabled systems ensures real-time monitoring, minimizing downtime and cost overruns.

4. Scale of Production

Economies of scale significantly reduce per-unit costs. Bulk orders enable manufacturers to distribute fixed costs (e.g., tooling, R&D) across larger volumes. For instance, producing 10,000 gears can lower costs by 25% compared to smaller batches. Filium’s large-scale production capabilities allow it to serve clients like Tata Motors and Mahindra Aerospace efficiently.

5. Import Duties and Taxes

India’s import duties on precision machinery components (10-15%) and GST (18%) inflate prices for imported gears. The ‘Make in India’ initiative encourages local production, reducing reliance on imports. Filium, a domestic leader, benefits from lower tariffs and offers prices 10-20% cheaper than imported alternatives.

6. Quality Standards and Certifications

Compliance with ISO 9001 and AS9100 certifications ensures reliability but involves rigorous testing and audits, adding 5-10% to costs. Filium’s ISO-certified facilities attract premium clients, justifying slightly higher prices while ensuring global standards.

7. Customization and Specialization

Custom gears for niche applications (e.g., aerospace) require tailored solutions, costing 30-50% more than standard gears. Filium’s R&D team collaborates with clients to design cost-effective bespoke gears, balancing innovation and affordability.

8. Geographic Location and Logistics

Proximity to industrial hubs (Pune, Chennai) reduces transportation costs. Filium’s strategic locations and partnerships with logistics firms ensure timely delivery, avoiding cost spikes from fuel price fluctuations or delays.

9. Market Demand

India’s automotive sector, growing at 8% CAGR, and expanding renewable energy projects drive demand for precision gears. The domestic precision engineering market is expected to reach $4.5 billion by 2025, increasing competition and price variability. Filium’s agile production adapts to demand surges, stabilizing prices.

10. Competition

With over 500 domestic gear manufacturers, competitive pricing is vital. Filium differentiates through quality, offering a 15% longer lifespan on gears compared to competitors, ensuring cost-effectiveness over time.

Filium Enterprises: A Case Study in Excellence

Established in 2005, Filium Enterprises has emerged as a leader in precision gear manufacturing. Their 50,000 sq. ft. facility in Pune houses 100+ CNC machines, producing 500,000+ gear units annually. By vertically integrating processes—from forging to热处理—Filium reduces lead times by 30% and costs by 20%. Their client portfolio includes Siemens, Hindustan Aeronautics Limited, and Bosch, underscoring their reputation for reliability. With a focus on R&D, Filium introduced eco-friendly polymer gears in 2023, capturing emerging markets in electric vehicles.

Conclusion

The price of precision gears in India is shaped by material, technological, and market dynamics. Filium Enterprises exemplifies how strategic investments in technology, scale, and quality can deliver cost-efficient solutions without compromising standards. As India’s industrial sector grows, suppliers like Filium will remain pivotal in balancing affordability and precision.