Understanding the Different Types of Mechanical Gears and Their Uses

Understanding the Different Types of Mechanical Gears and Their Uses

Mechanical gears are essential components in many industrial applications, providing efficient power transmission between shafts. From automotive engines to industrial machinery, gears play a crucial role in facilitating smooth and effective operation. As a result, understanding the different types of mechanical gears and their uses is important for anyone involved in the design, manufacturing, or maintenance of machines. This article will explore the various types of mechanical gears, their uses in different industries, and the role of Filiumenter gears India in supplying high-quality gears for a range of applications.

Table of Contents

What are Mechanical Gears?

Mechanical gears are toothed wheels used to transfer rotational motion and torque between machine components. By interlocking with each other, gears are able to transmit power efficiently, enabling the desired output speed, torque, or direction of motion. The size, shape, and arrangement of the gears influence their function and the type of application in which they can be used.

Types of Mechanical Gears and Their Uses

There are several types of mechanical gears, each designed for specific tasks. The main gear types include spur gears, bevel gears, helical gears, worm gears, and planetary gears. Each type has unique characteristics that make it suitable for specific industries and applications.

1. Spur Gears

Spur gears are one of the simplest and most commonly used types of mechanical gears. They consist of straight teeth mounted parallel to the shaft axis. Spur gears are ideal for transmitting power between two shafts that are parallel to each other.

- Applications: Spur gears are widely used in machinery, automotive applications, conveyors, and elevators.

- Advantages: Spur gears offer high efficiency and are easy to manufacture. They are best suited for low to medium-speed applications.

- Limitations: Due to their design, spur gears can generate noise and vibration at higher speeds, limiting their use in applications requiring quieter operation.

2. Bevel Gears

Bevel gears are used to transfer motion between two shafts that are typically at a 90-degree angle to each other. These gears are conical in shape, with teeth that are cut along the surface of the cone.

- Applications: Bevel gears are commonly used in automotive differentials, power tools, and industrial machines.

- Advantages: They can handle high torque and are highly effective at changing the direction of motion.

- Limitations: Bevel gears are more complex to manufacture, which can make them more expensive than other types.

3. Helical Gears

Helical gears have teeth that are cut at an angle to the axis of rotation, making them more efficient and quieter than spur gears. These gears are often used in applications where smooth and high-speed operations are critical.

- Applications: Helical gears are frequently used in industrial machinery, robotics, automotive engines, and elevators.

- Advantages: The angled teeth result in smoother meshing, which reduces noise and vibration. They also offer higher load capacities than spur gears.

- Limitations: Due to the slanted teeth, helical gears generate more axial thrust, which requires additional bearings to support the load.

4. Worm Gears

Worm gears are designed to transmit motion between non-intersecting and non-parallel shafts. The worm gear consists of a screw (the worm) and a gear (the worm wheel), which mesh at an angle. This configuration provides a significant reduction in speed and an increase in torque.

- Applications: Worm gears are commonly used in applications where space is limited, such as in gearboxes, hoists, and conveyor systems.

- Advantages: Worm gears provide high torque multiplication and compact designs.

- Limitations: Worm gears have lower efficiency due to sliding friction between the worm and wheel, which generates heat and wear over time.

5. Planetary Gears

Planetary gears are complex gear systems consisting of a central sun gear, multiple planet gears, and an outer ring gear. These gears are designed to provide high torque output while maintaining compactness.

- Applications: Planetary gears are commonly used in automatic transmissions in vehicles, robotics, and heavy-duty machinery.

- Advantages: They offer high torque output, efficiency, and durability while distributing load evenly among the gears.

- Limitations: Planetary gear systems can be more complex and expensive to design and maintain than simpler gear types.

Gear Types and Uses in Different Industries

Different industries require specific types of gears based on their power transmission needs. Understanding the gear types and their uses in various sectors is vital for selecting the right gear for the job.

- Automotive Industry: Gears play a vital role in the automotive industry, where they are used in engines, transmissions, and drive systems. Planetary gears and bevel gears are commonly used in automotive applications.

- Manufacturing Industry: In manufacturing, gears are essential for driving machinery, conveyors, and lifting equipment. Helical and spur gears are popular choices for high-efficiency machinery.

- Aerospace: The aerospace industry requires gears that can withstand high speeds and extreme conditions. Helical and bevel gears are often used in this sector.

- Construction and Mining: Heavy-duty machinery in construction and mining relies on durable and efficient gears, such as worm gears and planetary gears, to operate efficiently under tough conditions.

Filiumenter Gears India: Your Mechanical Gears Supplier

When looking for high-quality gears for various industrial applications, Filiumenter gears India stands out as a leading mechanical gears supplier in India. With an extensive range of gear types, including spur, helical, bevel, and planetary gears, Filiumenter offers products that cater to industries like automotive, manufacturing, and heavy machinery.

Filiumenter gears are manufactured to the highest standards, ensuring durability, efficiency, and reliability. Whether you are looking for custom gear solutions or standard gear types, Filiumenter gears India provides the best mechanical gears for your needs. As a trusted mechanical gears supplier in India, Filiumenter’s gears are engineered to meet international quality standards, making them a preferred choice for businesses across various sectors.

Conclusion

Understanding the different types of mechanical gears and their uses is essential for anyone involved in industrial machinery design and operation. From the simplicity of spur gears to the complexity of planetary gear systems, each type of gear serves a specific purpose in various applications.

By choosing the right gear for the task at hand, industries can ensure efficient power transmission, higher torque, and smoother operation. Filiumenter gears India continues to be a reliable mechanical gears supplier, offering high-quality products for various industries, ensuring that your machinery and equipment run smoothly and efficiently. When selecting gears, always consider the gear type, application, and supplier expertise to ensure optimal performance.

Related Products

Here are some useful statistics and facts to support the article on mechanical gears:

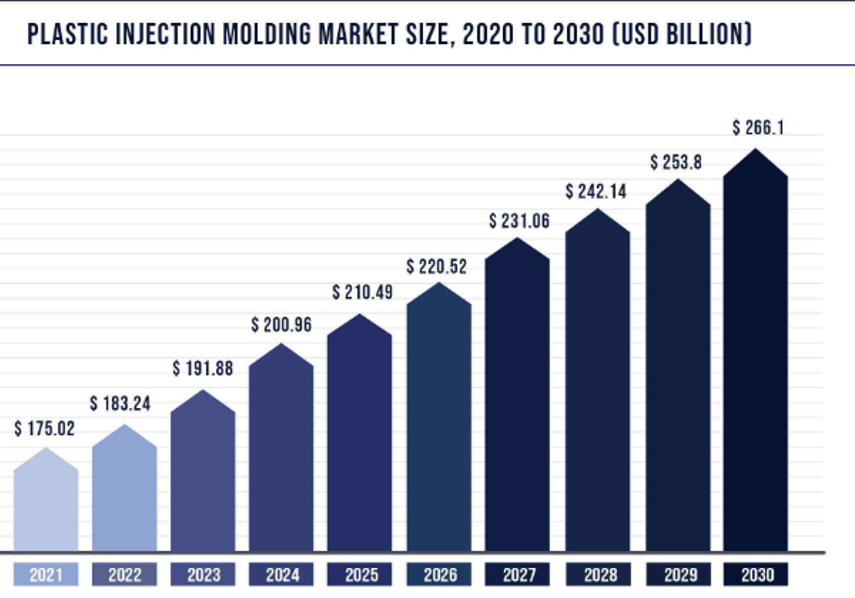

1. Global Gear Market Size

- The global gear market was valued at approximately USD 230 billion in 2022 and is expected to grow at a CAGR of around 5% from 2023 to 2030. This growth is driven by the increasing demand for gears in automotive, manufacturing, and industrial machinery sectors.

- Source: Grand View Research, 2023

2. Automotive Industry

- Over 60% of gears used in the automotive industry are bevel and helical gears, which are critical in the transmission systems of vehicles.

- The automotive sector consumes over 35% of the total gear market, highlighting its significant reliance on mechanical gears for transmissions, drivetrains, and differential systems.

- Source: MarketsandMarkets, 2022

3. Energy Efficiency in Gears

- Helical gears are known to offer efficiencies of up to 98%, making them ideal for high-performance applications such as in industrial machinery and automotive engines.

- Worm gears generally have lower efficiency, with typical values ranging from 30% to 50%. However, they are preferred in applications requiring high torque and compact designs.

- Source: Gear Technology, 2021

4. Industrial Machinery and Manufacturing

- In manufacturing, about 45% of industrial machinery relies on planetary gear systems due to their high torque capacity and compact design, ideal for heavy-duty operations such as in robots, conveyors, and gearboxes.

- Source: Machinery Lubrication, 2022

5. Global Gear Production

- China is the largest producer of gears globally, accounting for more than 30% of the global production. India follows closely, with a rapidly growing gear manufacturing industry due to increasing demand from sectors like automotive, agriculture, and industrial equipment.

- Source: The Economic Times, 2023

6. Growth of the Indian Gear Market

- The Indian gear market is expected to grow by 6.5% annually between 2023 and 2030, driven by increasing demand in sectors like automotive, construction, and heavy machinery.

- The demand for high-quality mechanical gears is particularly strong in India's automotive and manufacturing sectors, making suppliers like Filiumenter gears India increasingly essential in the market.

- Source: Business Wire India, 2023

7. Advantages of High-Quality Gears

- High-quality mechanical gears, such as those supplied by Filiumenter gears India, can reduce wear and tear in machinery by up to 50%, improving the lifespan of equipment and reducing downtime and maintenance costs.

- Source: Industrial Equipment Maintenance Journal, 2022

These statistics and facts provide insight into the growing importance and diverse applications of mechanical gears in various industries, emphasizing the demand for high-quality gear solutions like those offered by Filiumenter gears India.