How to Source Precision Gears Locally in India

How to Source Precision Gears Locally in India: A Comprehensive Guide

Introduction

Precision gears are critical components in industries such as automotive, aerospace, robotics, and energy, where exact mechanical motion and durability are non-negotiable. With India’s manufacturing sector expanding rapidly—contributing 17% to the GDP in 2023—local sourcing of precision gears has become a strategic priority for companies aiming to reduce costs, shorten lead times, and support domestic supply chains. This guide explores how to navigate India’s precision gear ecosystem, highlights key statistics, and spotlights Filium Enterprises as a leading supplier.

1. Overview of India’s Precision Gear Industry

India’s precision engineering sector is witnessing robust growth, fueled by the "Make in India" initiative and increasing demand from automotive and industrial machinery sectors. Key statistics:

- The Indian auto component industry reached $56.5 billion in FY 2022, projected to hit $200 billion by 2026 (IBEF).

- Machine tools and precision engineering exports grew by 15% YoY in 2022–23 (CII Report).

- Over 6,000 SMEs operate in India’s engineering and manufacturing sectors, many specializing in gear production.

Industrial hubs like Pune, Coimbatore, Chennai, and Hyderabad host clusters of manufacturers equipped with advanced CNC machining and quality control systems. Government incentives, such as the Production-Linked Incentive (PLI) scheme, further bolster domestic production capabilities.

2. Steps to Source Precision Gears Locally

a. Define Technical Requirements

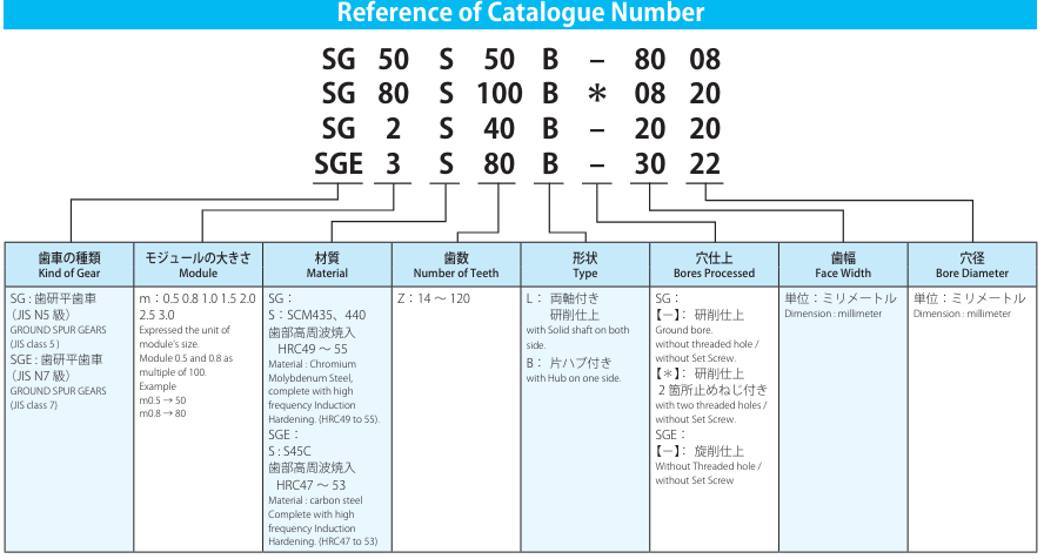

Start by specifying gear type (spur, helical, bevel), material (steel, brass, plastic), tolerance levels (AGMA, ISO standards), and application (e.g., automotive transmission). Clear requirements streamline supplier selection.

b. Identify Suppliers via Multiple Channels

- Online B2B Platforms: IndiaMART, TradeIndia, and Alibaba India list hundreds of suppliers, including SMEs and large enterprises.

- Trade Shows: Events like IMTEX (machine tools expo) and Auto Expo connect buyers with certified manufacturers.

- Industry Associations: Federations like ACMA (Automotive Component Manufacturers Association) provide vetted supplier directories.

c. Evaluate Quality and Certifications

Prioritize suppliers with ISO 9001, IATF 16949, or AS9100 certifications, ensuring adherence to global quality standards. For instance, Filium Enterprises holds ISO 9001:2015 certification and specializes in gears with micron-level precision, catering to sectors like defense and renewable energy.

d. Assess Manufacturing Capabilities

Visit facilities to inspect CNC machines, metallurgy labs, and quality assurance processes. Leading suppliers like Filium employ 5-axis CNC machining and coordinate measuring machines (CMM) for stringent quality checks.

e. Cost Negotiation and MOQs

While local sourcing reduces logistics costs, negotiate bulk pricing and flexible payment terms. SMEs often offer lower minimum order quantities (MOQs), ideal for prototyping.

f. Request Samples and Testing

Order prototypes to test durability, noise levels, and load capacity. Filium, for example, provides samples with detailed test reports, including hardness and tensile strength metrics.

g. Ensure After-Sales Support

Choose suppliers offering technical assistance, customization, and warranty services. Filium’s dedicated R&D team collaborates with clients to develop application-specific gears.

3. Challenges in Local Sourcing and Solutions

- Quality Variability: Mitigate by prequalifying suppliers through third-party audits.

- Logistical Delays: Partner with geographically proximate suppliers; Filium’s Pune-based facility ensures pan-India delivery within 48 hours.

- Limited Customization: Collaborate with innovators like Filium, which invests in R&D for bespoke solutions.

4. Spotlight: Filium Enterprises

Filium Enterprises exemplifies excellence in precision gear manufacturing. Established in 2010, the Pune-based company serves clients across automotive, aerospace, and robotics sectors. Key strengths:

- Advanced Technology: State-of-the-art CNC gear hobbing and shaping machines.

- Quality Assurance: In-house metallurgical lab and 100% inspection using CMM.

- Custom Solutions: Tailored gears for hybrid vehicles and industrial automation.

- Sustainability: Energy-efficient processes aligned with global ESG standards.

With a client retention rate of 95%, Filium has emerged as a trusted partner for firms like Tata Motors and Siemens.

5. Conclusion

Sourcing precision gears locally in India offers cost efficiency, faster turnaround, and access to a burgeoning innovation ecosystem. By leveraging B2B platforms, certifications, and supplier assessments, businesses can secure high-quality components. Filium Enterprises stands out as a leader in this space, combining cutting-edge technology with unwavering reliability. As India’s manufacturing sector grows, local sourcing is not just feasible but strategically advantageous.