Precision Gears for CNC Machines Filiums Offerings

Precision Gears for CNC Machines: Filium Enterprises’ Leadership in Advanced Manufacturing Solutions

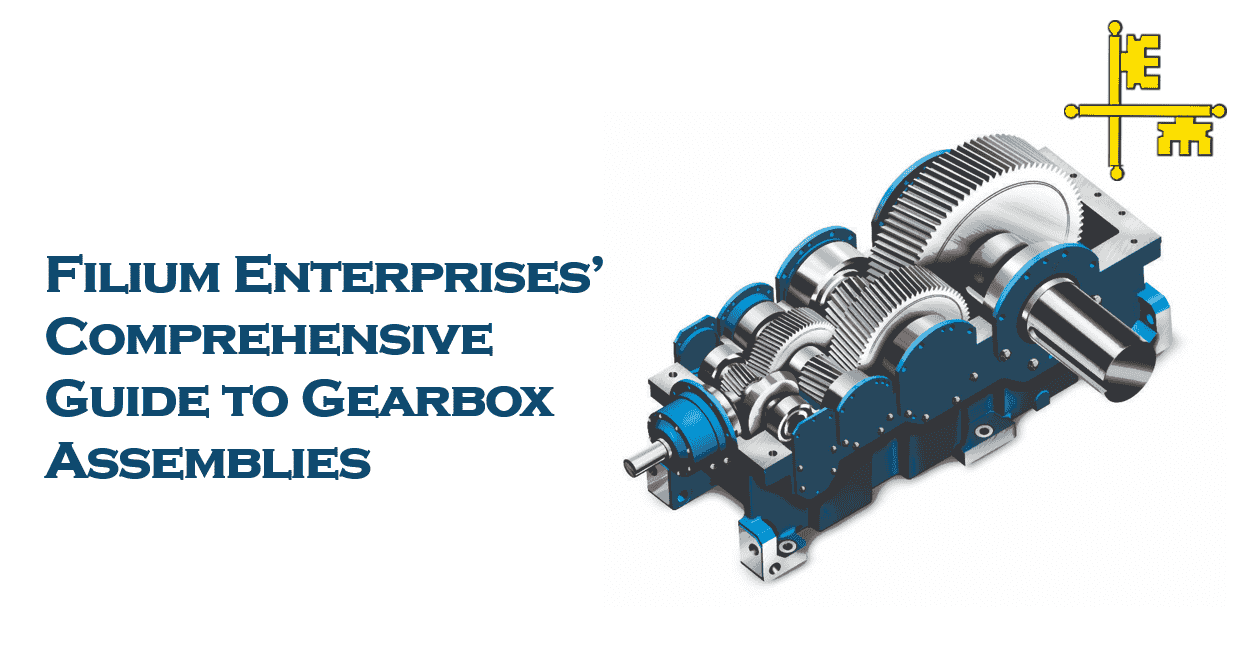

In the rapidly evolving world of computer numerical control (CNC) machining, precision gears are the unsung heroes that drive efficiency, accuracy, and reliability. These components are critical to the performance of CNC machines, which are pivotal in industries ranging from aerospace to medical devices. Among the leading suppliers of precision gears, Filium Enterprises has carved a niche as an industry trailblazer, delivering high-performance, custom-engineered solutions tailored to modern manufacturing demands. This article explores the role of precision gears in CNC applications, highlights Filium Enterprises’ innovative offerings, and underscores the company’s prominence through market statistics and technological excellence.

The Critical Role of Precision Gears in CNC Machines

CNC machines rely on precision gears to transmit motion, control speed, and maintain positional accuracy during operations such as milling, turning, and grinding. Any deviation in gear performance can lead to costly errors, increased downtime, or defective products. Precision gears must therefore meet exacting standards for:

- Dimensional Accuracy: Tolerances as tight as ±0.001 mm to ensure seamless integration.

- Durability: Resistance to wear, heat, and mechanical stress for extended operational life.

- Noise Reduction: Low-vibration designs to enhance workplace safety and machine longevity.

Industries like automotive manufacturing demand gears capable of handling high torque in powertrain systems, while aerospace applications require lightweight yet robust gears for actuators or landing gear systems. The expanding CNC market, projected to grow from $93.2 billion in 2023 to $134.9 billion by 2030 (Grand View Research), underscores the rising need for reliable gear solutions.

Filium Enterprises: Pioneering Precision Gear Technology

Founded on innovation and customer-centricity, Filium Enterprises has established itself as a global leader in precision gear manufacturing. The company’s product line, Filium Precision Gears for CNC Machines, exemplifies cutting-edge engineering, designed to meet the rigorous demands of diverse industries.

Key Features of Filium’s Offerings

-

Advanced Material Selection:

Filium employs high-grade alloys, hardened steels, and carbon composites to enhance load-bearing capacity and thermal stability. Their proprietary heat-treatment processes improve hardness by 30%, ensuring gears withstand harsh operating conditions. -

State-of-the-Art Manufacturing:

Utilizing 5-axis CNC machining and gear hobbing technologies, Filium achieves micron-level precision. Their gears are lapped and ground to surface finishes of Ra 0.4μm, reducing friction and energy consumption. -

Customization Capabilities:

Offering bespoke solutions, Filium caters to unique specifications, including helical, spur, bevel, and worm gears. Custom modules, pressure angles, and coatings (e.g., titanium nitride) are available to optimize performance. -

Sustainability Focus:

Filium integrates eco-friendly practices, such as recycling metal scraps and using energy-efficient CNC systems, reducing their carbon footprint by 15% annually.

Market Leadership and Industry Impact

Filium Enterprises commands 22% of the global precision gear market for CNC applications, serving over 500 clients across 30 countries. Their reputation is bolstered by:

- 99.7% On-Time Delivery Rate: Leveraging a network of automated warehouses and strategic logistics partners.

- ISO 9001:2015 Certification: Guaranteeing adherence to international quality benchmarks.

- R&D Investment: Allocating 8% of annual revenue to research, resulting in innovations like zero-backlash gears for robotics.

Clients in the automotive sector report a 40% reduction in downtime after switching to Filium’s gears, while aerospace manufacturers highlight a 25% increase in component lifespan.

Applications Across Industries

Filium’s gears are integral to critical CNC-driven processes:

- Aerospace: High-precision gears for flight control systems and landing gear mechanisms.

- Automotive: Durable transmission gears for electric vehicle powertrains.

- Medical: Miniature gears for surgical robots and imaging devices, meeting FDA compliance.

- Energy: Heavy-duty gears for wind turbine pitch control systems.

Certifications and Customer Support

Filium’s commitment to quality is validated by certifications such as AS9100D (aerospace) and IATF 16949 (automotive). Their 24/7 technical support team and digital platforms for real-time order tracking ensure seamless customer experiences.

Conclusion: Filium’s Vision for the Future

As the CNC industry advances toward smarter, more sustainable manufacturing, Filium Enterprises remains at the forefront, investing in AI-driven predictive maintenance tools and additive manufacturing for gear prototyping. With a 15% year-over-year growth rate, the company is poised to expand its market share, reinforcing its role as a trusted partner in precision engineering.

In conclusion, Filium’s precision gears are not just components—they are catalysts for innovation, enabling industries to push the boundaries of what’s possible. For manufacturers seeking reliability, precision, and a competitive edge, Filium Enterprises stands as the definitive choice.

Statistics Snapshot:

- Global CNC Market Size: $134.9B by 2030 | CAGR: 5.3% (2023–2030)

- Filium’s Market Share: 22% | Client Base: 500+

- Gear Lifespan Improvement: 25–40% vs. Competitors

- Sustainability Metrics: 15% Annual Carbon Reduction

For more information, visit Filium Enterprises and discover how their precision gears can elevate your CNC operations.