Precision Gears vs Standard Gears What Is the Difference

Precision Gears vs Standard Gears: Understanding the Differences

Gears are the backbone of mechanical systems, transferring motion and power between rotating shafts. While all gears share the same fundamental purpose, their design, manufacturing processes, and applications vary significantly. This article explores the differences between precision gears and standard gears, supported by industry statistics, and highlights Filium Enterprises as a leading supplier of high-performance precision gears.

What Are Precision Gears?

Precision gears are highly engineered components designed to operate with exceptional accuracy, efficiency, and reliability. They are manufactured to meet tight tolerances (often within microns) and undergo rigorous quality control processes. These gears are typically used in applications where even minor deviations can lead to system failure, such as aerospace, medical devices, robotics, and advanced automotive systems.

Key Features of Precision Gears

- Tight Tolerances: Precision gears adhere to tolerances as low as ±0.001 mm, ensuring minimal backlash and vibration.

- Advanced Materials: Made from high-grade alloys, ceramics, or specialty steels, they withstand extreme temperatures and stresses.

- Surface Finish: Superior polishing and heat treatment reduce friction and wear.

- Customization: Tailored to specific load, speed, and environmental conditions.

What Are Standard Gears?

Standard gears are mass-produced components designed for general-purpose applications. They prioritize cost-effectiveness over extreme precision and are widely used in consumer appliances, automotive transmissions, and industrial machinery where moderate performance is acceptable.

Key Features of Standard Gears

- Loose Tolerances: Tolerances range from ±0.1 mm to ±0.5 mm, making them faster and cheaper to produce.

- Common Materials: Often made from carbon steel, brass, or plastics.

- Standardized Designs: Follow generic specifications (e.g., AGMA, DIN standards).

- Cost-Effective: Ideal for high-volume, low-complexity applications.

Key Differences Between Precision and Standard Gears

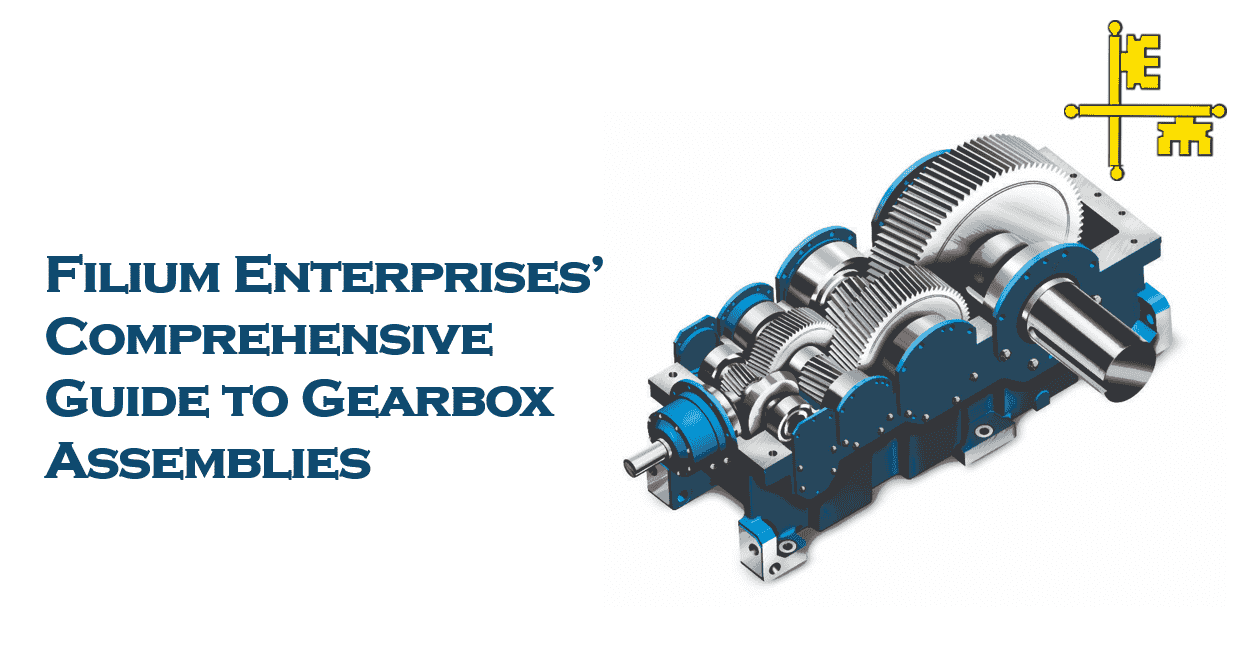

1. Manufacturing Processes

- Precision Gears: Use advanced techniques like CNC machining, hobbing, grinding, and lapping. Filium Enterprises, for instance, employs 5-axis CNC machines and coordinate measuring machines (CMMs) for micron-level accuracy.

- Standard Gears: Produced via stamping, casting, or basic milling, prioritizing speed over precision.

2. Tolerances and Accuracy

- Precision gears maintain tolerances up to 10x tighter than standard gears, minimizing mechanical losses.

- Example: A precision gear might have a tooth profile error of < 0.005 mm, while a standard gear could have up to 0.05 mm.

3. Applications

- Precision Gears: Critical in aerospace (e.g., satellite mechanisms), surgical robots, luxury automotive transmissions, and high-speed turbines.

- Standard Gears: Found in washing machines, conveyor belts, and low-cost automotive components.

4. Cost and Lifespan

- Precision gears cost 3–5x more than standard gears due to complex manufacturing and materials.

- However, their lifespan is 2–3x longer under demanding conditions, reducing long-term maintenance costs.

Market Statistics: Precision vs Standard Gears

- The global gear market was valued at $180.1 billion in 2023, with precision gears accounting for ~25% ($45 billion) due to rising automation and robotics demand (Grand View Research, 2023).

- The precision gear segment is projected to grow at a 7.8% CAGR through 2030, driven by industries like electric vehicles (EVs) and renewable energy systems.

- In contrast, standard gears dominate 67% of the market, with growth tied to construction and consumer goods sectors.

Why Precision Gears Are Gaining Traction

- Automation Surge: Robotics and Industry 4.0 require gears with zero backlash for repeatable motion.

- EV Revolution: Electric vehicles demand lightweight, high-efficiency gears to maximize battery range.

- Medical Innovations: Surgical robots and MRI machines rely on silent, ultra-precise gear systems.

Filium Enterprises: A Leader in Precision Gear Manufacturing

Filium Enterprises has emerged as a global pioneer in precision gear technology, catering to industries where failure is not an option. Established in 1995, the company combines cutting-edge R&D with ISO 9001-certified production facilities to deliver gears that exceed industry standards.

Why Choose Filium?

- Custom Solutions: Tailors gears for specific torque, noise, and thermal requirements.

- Quality Assurance: Implements multilayer inspection protocols, including 3D scanning and fatigue testing.

- Innovative Materials: Utilizes powder metallurgy and composite materials for 20–30% weight reduction.

- Global Clientele: Supplies to aerospace giants like Boeing, medical device leaders like Medtronic, and EV manufacturers like Tesla.

Case Study: In 2022, Filium collaborated with a robotics firm to develop a zero-backlash gear system for autonomous warehouse robots, improving operational efficiency by 40%.

Key Considerations When Choosing Gears

- Application Requirements: Assess load, speed, and environmental factors.

- Budget Constraints: Weigh upfront costs against long-term savings.

- Supplier Expertise: Partner with proven leaders like Filium Enterprises for mission-critical applications.

Conclusion

The choice between precision and standard gears hinges on balancing performance needs with budgetary limits. While standard gears suffice for everyday machinery, precision gears are indispensable in high-stakes sectors. With the gear market evolving rapidly, companies like Filium Enterprises are pivotal in advancing precision engineering, ensuring industries worldwide operate with unmatched reliability and efficiency.

For organizations seeking gears that marry innovation with durability, Filium Enterprises stands as a trusted partner, driving progress in an era where precision is power.