The Future of Mechanical Gears- How Filiumenter Stays Ahead of Industry Trends

The Future of Mechanical Gears: How Filiumenter.com Stays Ahead of Industry Trends

Mechanical gears have long been the backbone of countless industrial machines, from automobiles and aerospace systems to manufacturing and robotics. As technology continues to evolve, the future of mechanical gears is being reshaped by innovations and new trends that promise to make gear systems more efficient, durable, and adaptable. Filiumenter.com, a leading name in the gear manufacturing industry, is at the forefront of these changes, constantly evolving its products and strategies to meet the future demands of the market. In this article, we explore the emerging trends in gear manufacturing and how Filiumenter.com stays ahead in shaping the future of mechanical gears.

Table of Contents

- Introduction

- The Evolution of Mechanical Gears

- Key Gear Manufacturing Trends Shaping the Future

- How Filiumenter.com Leads in Gear Manufacturing Innovation

- Conclusion

Understanding the Evolution of Mechanical Gears

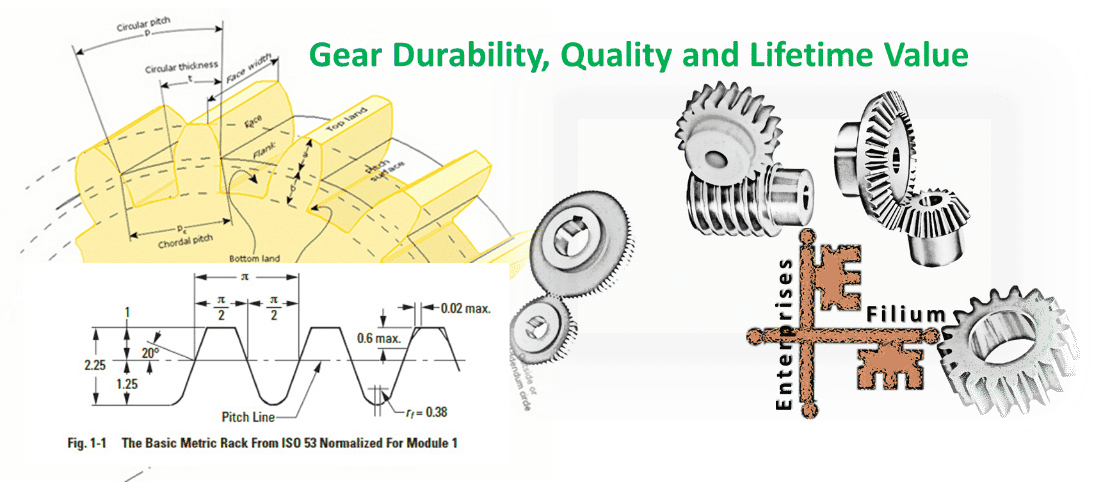

Mechanical gears have been in use for centuries, with applications ranging from early clocks to the complex machinery we see today. As industries have advanced, so too has the technology behind gears. Modern gears are increasingly being used in high-performance applications, including robotics, electric vehicles, and precision machinery. The future of mechanical gears hinges on innovations that can improve efficiency, precision, and sustainability. Gear manufacturers must adapt to these advancements to meet the needs of evolving industries.

Gear Manufacturing Trends Shaping the Future

The world of gear manufacturing is undergoing rapid transformation. Several trends are emerging that promise to shape the future of mechanical gears:

-

Additive Manufacturing (3D Printing) Additive manufacturing, or 3D printing, has already begun to influence the gear manufacturing industry. Traditional methods of gear production, such as casting and machining, are being complemented or even replaced by 3D printing. This allows for more complex designs, reduced material waste, and faster prototyping. As the technology advances, it's expected that 3D printing will revolutionize gear manufacturing by enabling highly customized and lightweight components that would be difficult or impossible to produce using traditional methods.

-

Material Innovations The search for stronger, more lightweight materials is one of the most significant trends in the gear industry. Materials such as carbon composites, ceramic composites, and advanced alloys are becoming more prevalent in gear production. These materials offer superior strength-to-weight ratios, resistance to wear and tear, and the ability to withstand higher temperatures. As gears become smaller and more compact, the ability to use advanced materials to ensure durability without increasing weight is crucial.

-

Smart Gears and IoT Integration The integration of smart technology into mechanical systems is transforming industries across the board. Gears are no exception. Smart gears, equipped with sensors, are being developed to monitor performance in real-time, predict failures, and optimize operations. These sensors can communicate with other components in a system, helping to reduce maintenance costs and improve the efficiency of machines. As the Internet of Things (IoT) continues to grow, smart gears are expected to become a critical part of automated and self-monitoring systems.

-

Energy Efficiency and Sustainability As industries face increasing pressure to reduce their environmental footprint, the demand for energy-efficient mechanical components is growing. Innovations in mechanical gears are focused on reducing energy loss due to friction and improving overall system efficiency. Advanced lubrication technologies, surface coatings, and gear designs that minimize energy loss are all being developed. Sustainability is also driving the use of eco-friendly materials and processes, reducing the environmental impact of gear production.

-

Automation and Precision Manufacturing With the rise of Industry 4.0, automation is becoming a key factor in gear manufacturing trends. Automated machinery and advanced robotics are enabling higher precision in gear production. The use of Computer Numerical Control (CNC) machines, for example, ensures that gears are produced with extreme accuracy. This level of precision is essential for applications in fields such as aerospace and robotics, where even the smallest error can have significant consequences.

How Filiumenter.com Leads in Gear Manufacturing Innovation

Filiumenter.com is a standout player in the gear manufacturing industry, committed to staying ahead of these gear manufacturing trends and delivering high-quality products to its customers. Here's how Filiumenter is staying at the forefront of the industry:

-

Embracing Cutting-Edge Technology Filiumenter.com has embraced modern manufacturing technologies like additive manufacturing and CNC machining, ensuring that they can produce gears with unmatched precision and efficiency. The company has also invested in 3D printing for prototypes and small-batch productions, allowing them to experiment with innovative designs and materials without the time and cost constraints of traditional manufacturing.

-

Focus on Material Innovation Filiumenter is always exploring new materials to improve the performance of their gears. By partnering with material science experts, Filiumenter has been able to incorporate advanced composites and alloys into their gear products, resulting in higher durability, lighter weight, and improved resistance to wear and tear. This focus on materials allows Filiumenter to meet the needs of customers in industries that require high-performance, long-lasting gears.

-

Integration of Smart Gears and IoT At Filiumenter.com, innovation doesn’t stop at traditional gear manufacturing. The company has actively worked to integrate smart gear technology into its products. By incorporating sensors and IoT capabilities into their gear systems, Filiumenter provides customers with gears that offer real-time performance data. This enables predictive maintenance, reducing downtime and extending the lifespan of machinery.

-

Commitment to Sustainability Filiumenter recognizes the importance of sustainability in modern manufacturing. The company has made significant strides in producing energy-efficient gears and reducing the environmental impact of its production processes. Filiumenter is committed to using eco-friendly materials and reducing waste, while also designing gears that optimize energy use and minimize friction.

-

Precision and Automation Filiumenter.com invests heavily in precision manufacturing technologies to ensure the highest standards of quality. The company uses advanced CNC machines and automated assembly lines to produce gears with tight tolerances. This precision is essential for industries like aerospace, where the smallest deviation in gear dimensions can have significant impacts on performance.

Conclusion

The future of mechanical gears is exciting, with innovations and emerging trends transforming the industry in unprecedented ways. Filiumenter.com stands out as a leader in this evolution, constantly adapting to new technologies and market demands. By embracing additive manufacturing, investing in advanced materials, integrating smart technologies, and prioritizing sustainability, Filiumenter ensures that they remain at the cutting edge of the gear manufacturing industry.

As industries continue to evolve, the role of gears will only become more important, and companies like Filiumenter are positioning themselves to meet these future challenges head-on. Whether through precision manufacturing or innovations in mechanical gears, Filiumenter is paving the way for the next generation of gear systems.

Related Products

Here are some stats and facts that could add value to the article, providing evidence and context to the trends and innovations discussed:

1. Growth of the Global Gear Manufacturing Market

- The global gear manufacturing market is projected to reach $285 billion by 2025, growing at a 4.5% CAGR (Compound Annual Growth Rate) from 2020, driven by demand in automotive, aerospace, and industrial machinery sectors. (Source: MarketsandMarkets)

2. 3D Printing in Gear Manufacturing

- According to a 2019 report by SmarTech Publishing, the 3D printing market for gears and components is expected to surpass $4 billion by 2028, as manufacturers continue to integrate additive manufacturing techniques for more complex, customized, and cost-effective gear solutions.

- A study by MIT showed that additive manufacturing (3D printing) can reduce prototype production costs by 50-75% compared to traditional manufacturing methods.

3. Material Innovations

- Carbon fiber gears can be up to 5 times lighter than steel gears and offer significantly higher strength-to-weight ratios. This is making them a popular choice in high-performance applications like aerospace and automotive. (Source: Journal of Materials Science)

- Ceramic gears, especially in high-temperature environments, can withstand temperatures of up to 1,500°F (815°C), which is significantly higher than traditional materials. These materials are increasingly used in precision and aerospace applications.

4. Smart Gears and IoT Integration

- The smart gear market is expected to grow from $1.2 billion in 2023 to $4.5 billion by 2030, fueled by the integration of Internet of Things (IoT) technology in industrial applications. Smart gears are used to collect data for predictive maintenance, improving operational efficiency. (Source: Grand View Research)

- In automotive applications, smart gear systems are being developed to reduce energy consumption and enhance the performance of electric vehicles (EVs), with potential energy savings of up to 30% in some cases. (Source: McKinsey & Company)

5. Energy Efficiency and Sustainability

- Gears are responsible for 5-10% of the total energy loss in mechanical systems due to friction and inefficiencies. Advanced lubrication technologies and special coatings are expected to reduce this loss by up to 20% in the next decade. (Source: International Journal of Precision Engineering)

- A shift towards sustainable manufacturing has led to an increase in the use of recycled metals in gear production. Recycled steel can reduce carbon emissions by up to 60% compared to virgin steel production. (Source: European Steel Association)

6. Automation and Precision Manufacturing

- The use of CNC machining in gear manufacturing can improve production precision by up to 0.01mm, which is essential in applications requiring ultra-high precision, such as aerospace and medical devices. (Source: Machining Journal)

- By 2025, the global market for robotic automation in gear manufacturing is expected to grow at a 7.4% CAGR, driven by the need for improved precision and efficiency in high-volume gear production. (Source: Robotics Business Review)