Types of Spiral Bevel Gears Produced by Filium: A Comprehensive Guide

Types of Spiral Bevel Gears Produced by Filium: A Comprehensive Guide

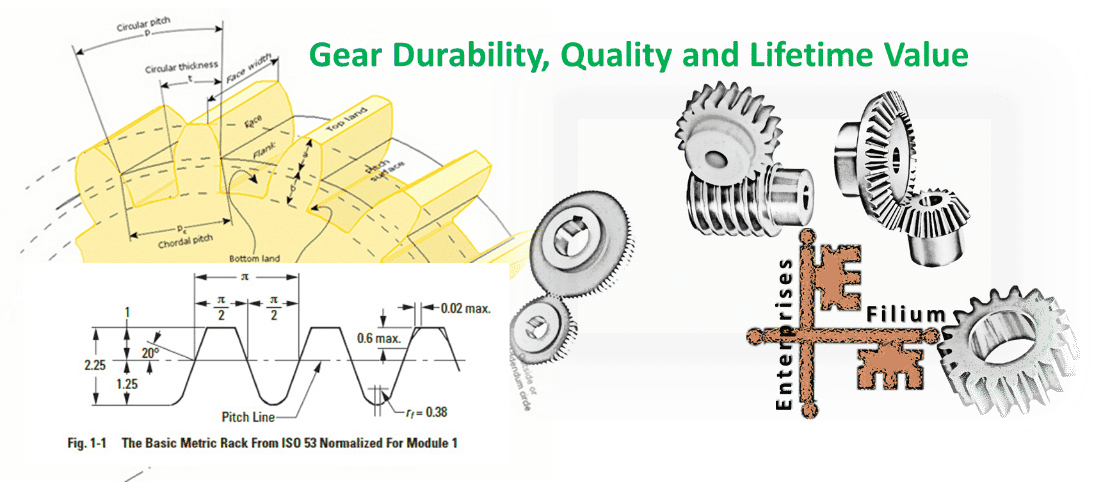

Spiral bevel gears are widely used across industries for applications requiring high efficiency, precise motion, and the ability to transmit power at various angles. These gears are defined by their spiral-shaped teeth and are mainly used in machinery that requires the transmission of torque and rotational motion at a right angle. Filium is a leading supplier of high-quality spiral bevel gears, delivering precision-engineered components for various sectors including automotive, aerospace, industrial machinery, and more.

In this article, we explore the different types of spiral bevel gears offered by Filium, their specifications, and their applications in various engineering fields. This article will provide detailed insights into why these gears are essential in specific industrial applications, and how Filium’s products meet the demands of design engineers. For those looking to buy spiral bevel gears in India, Filium offers an extensive range suitable for high-performance applications.

Types of Spiral Bevel Gears

Spiral bevel gears produced by Filium can be classified based on their geometry, design characteristics, and applications. These gears come in a variety of shapes and specifications to cater to different engineering needs. Below are the main types available:

1. Standard Spiral Bevel Gears

- Design: Standard spiral bevel gears have curved teeth at an angle to the gear face, allowing for gradual engagement and smooth power transmission.

- Specification Range:

- Module: 1.5 to 8.0

- Diameters: 40 mm to 500 mm

- Tooth Counts: 16 to 160 teeth

- Material: Case-hardened steel, Alloy steel, or Stainless steel

Applications: Standard spiral bevel gears are commonly used in automotive differentials, marine propulsion systems, and general industrial applications that require high torque and minimal noise. The gradual engagement of the teeth makes these gears ideal for smooth motion transfer.

2. Hypoid Spiral Bevel Gears

- Design: Hypoid gears are similar to spiral bevel gears but differ in that their axes are non-intersecting. This design allows for greater load-carrying capacity and smoother operation at high speeds.

- Specification Range:

- Module: 2.0 to 10.0

- Diameters: 60 mm to 600 mm

- Tooth Counts: 20 to 200 teeth

- Material: Alloy steel, Carbon steel

Applications: Hypoid spiral bevel gears are primarily found in automotive drive systems, especially in rear-wheel-drive and four-wheel-drive vehicles, where they offer smoother operation and greater power efficiency compared to standard gears.

3. Zerol Spiral Bevel Gears

- Design: Zerol bevel gears are a special type of spiral bevel gear with zero-degree spiral angles. These gears combine the characteristics of both straight and spiral bevel gears, providing smoother transitions without the complexity of spiraled teeth.

- Specification Range:

- Module: 1.5 to 6.0

- Diameters: 50 mm to 400 mm

- Tooth Counts: 20 to 120 teeth

- Material: Alloy steel, Case-hardened steel

Applications: Zerol gears are suitable for applications where smooth engagement is required but the load conditions do not necessitate high spiral angles. Typical applications include aerospace control systems and precision mechanical devices.

4. High-Contact Ratio Spiral Bevel Gears

- Design: These gears are engineered with optimized tooth geometries to increase the contact ratio, reducing the stress on individual teeth and enhancing load distribution.

- Specification Range:

- Module: 1.5 to 5.0

- Diameters: 80 mm to 300 mm

- Tooth Counts: 30 to 150 teeth

- Material: Case-hardened steel, Alloy steel

Applications: High-contact ratio spiral bevel gears are ideal for applications requiring increased load capacity and quiet operation, such as machine tools, industrial robots, and heavy-duty machinery.

Table of Specifications and Applications

| Gear Type | Module Range | Diameter Range (mm) | Tooth Count Range | Material | Common Applications |

|---|---|---|---|---|---|

| Standard Spiral Bevel Gear | 1.5 - 8.0 | 40 - 500 | 16 - 160 | Case-hardened steel, Alloy steel | Automotive differentials, industrial machinery, marine propulsion |

| Hypoid Spiral Bevel Gear | 2.0 - 10.0 | 60 - 600 | 20 - 200 | Alloy steel, Carbon steel | Automotive drive systems, rear-wheel-drive, four-wheel-drive |

| Zerol Spiral Bevel Gear | 1.5 - 6.0 | 50 - 400 | 20 - 120 | Alloy steel, Case-hardened steel | Aerospace control systems, precision mechanical devices |

| High-Contact Ratio Spiral Bevel Gear | 1.5 - 5.0 | 80 - 300 | 30 - 150 | Case-hardened steel, Alloy steel | Machine tools, industrial robots, heavy-duty machinery |

Detailed Application Analysis

Automotive Industry

One of the primary industries that rely on spiral bevel gears is the automotive sector, particularly in the manufacturing of differentials. Standard and hypoid spiral bevel gears are frequently used in vehicle transmission systems to transfer torque from the engine to the wheels. The hypoid gear's ability to handle high loads and operate quietly under heavy-duty conditions makes it the go-to choice for trucks and large SUVs.

In automotive differentials, spiral bevel gears are critical for ensuring smooth handling and efficient power transmission. They allow the vehicle’s wheels to rotate at different speeds, crucial for cornering without slippage or excessive tire wear. The use of alloy steel in Filium’s gears ensures longevity and high strength, even under the demanding conditions of automotive use.

Aerospace Industry

Zerol spiral bevel gears find their application in the aerospace industry, where precision, weight-saving, and smooth operation are of utmost importance. These gears are used in flight control systems, actuators, and other precision components in aircraft. The zero-degree spiral angle of Zerol gears offers a balance between the smooth operation of spiral bevel gears and the simplicity of straight bevel gears, making them a preferred choice in applications where vibration and noise reduction are critical.

For instance, in helicopter transmission systems, Zerol gears are used to manage power transfer between the engine and the rotor blades. The smooth engagement provided by the spiral design minimizes vibration, contributing to quieter and more efficient flight control.

Industrial Machinery

In the realm of industrial machinery, high-contact ratio spiral bevel gears are vital for machines that require efficient power transmission with reduced wear and tear. Machine tools, industrial robots, and heavy-duty machinery rely on these gears to handle high loads while maintaining precision.

For example, in CNC machines, the precise motion and high load capacity of high-contact ratio spiral bevel gears enable efficient cutting, milling, and drilling operations. The optimized tooth design ensures even load distribution, prolonging the life of the machine and ensuring accuracy over extended periods of operation.

Marine Propulsion Systems

Marine vessels require gears that can withstand high torque and operate smoothly under extreme conditions. Spiral bevel gears are used in marine propulsion systems, where they transmit power from the engine to the propeller shaft. The gradual engagement of spiral teeth ensures that power is transmitted efficiently without causing excessive noise or vibration, which is crucial in maintaining the integrity of marine vessels over long periods of operation.

Filium’s spiral bevel gears, made from corrosion-resistant materials, are particularly suited for this application, ensuring durability in the harsh marine environment.

Related Products

Why Choose Filium for Spiral Bevel Gears?

Filium supplies a wide range of spiral bevel gears designed for applications across multiple industries, offering a combination of precision, durability, and flexibility. With years of experience in gear manufacturing and supplying, Filium gears are engineered to meet the stringent demands of modern industrial environments, providing reliable performance and enhanced efficiency.

Here are some key reasons why design engineers should choose Filium for their spiral bevel gear needs:

1. Precision Engineering

Filium’s spiral bevel gears are produced using state-of-the-art manufacturing processes to ensure high precision in gear alignment and smooth operation. This precision is crucial in applications such as automotive differentials, CNC machines, and aerospace control systems, where even minor misalignments can lead to significant performance issues.

2. High-Quality Materials

Filium uses premium materials (Sourced in Japan, Taiwan and USA) such as case-hardened steel, alloy steel, and carbon steel to manufacture gears, ensuring they can withstand the high loads and stresses encountered in demanding applications. This makes Filium's gears durable and capable of handling high-torque environments, such as marine propulsion and heavy-duty industrial machinery.

3. Customization Options

Filium offers custom solutions for spiral bevel gears to suit specific industrial needs. Whether it’s a particular material requirement or specific design characteristics, Filium works closely with engineers to design gears that meet the exacting demands of their projects.

4. Corrosion Resistance

For applications such as marine propulsion systems, where exposure to water and other harsh conditions is inevitable, Filium's gears are designed with corrosion-resistant properties, ensuring long-term performance and reliability in marine environments.

5. Increased Load Capacity

High-contact ratio spiral bevel gears supplied by Filium are designed for optimal load distribution, reducing stress on individual teeth and increasing the overall load-carrying capacity. This feature is particularly beneficial for industrial applications such as machine tools and industrial robots, where high precision and load management are critical.

Spiral Bevel Gear Applications: Industry Overview

The use of spiral bevel gears in various industries continues to grow as demand for more efficient and durable motion transmission solutions increases. Below is an industry-specific overview of some of the critical applications where Filium’s spiral bevel gears excel:

Automotive Sector

In automotive applications, spiral bevel gears are crucial for differentials, where power needs to be transferred from the engine to the wheels at different speeds, especially when cornering. These gears ensure smooth operation and high torque efficiency. Filium’s precision-engineered spiral bevel gears are ideal for performance vehicles, trucks, and SUVs, providing durability and smooth power transmission. The application of hypoid spiral bevel gears further enhances torque capacity and reduces noise, contributing to a more comfortable driving experience.

Aerospace

The aerospace sector demands lightweight and highly precise components for control systems, actuators, and power transmission. Zerol spiral bevel gears from Filium are extensively used in flight control mechanisms, where weight savings and precise engagement are paramount. In helicopter transmissions, these gears ensure power transfer from engines to rotors without causing vibrations or undue wear, thus contributing to the safety and longevity of aerospace systems.

Industrial Robotics

Spiral bevel gears are widely used in industrial robots, which require high precision and torque capacity to operate efficiently. Filium's gears are designed to meet the demands of modern robotics, offering smooth motion transfer and reduced wear over extended operation periods. High-contact ratio spiral bevel gears are particularly beneficial in this context, as they provide optimal load distribution, reducing maintenance needs and increasing robot uptime.

Machine Tools

In machine tools, spiral bevel gears are essential for the efficient operation of cutting, milling, and drilling machines. These gears ensure precise rotational motion, helping in the production of high-quality components. Filium’s spiral bevel gears are ideal for CNC machines and other precision tools that require reliable and accurate motion control.

Marine Applications

Spiral bevel gears are used in marine propulsion systems to transmit power from the engine to the propeller shaft. Given the harsh conditions in marine environments, gears need to withstand high levels of torque and exposure to water. Filium’s corrosion-resistant spiral bevel gears ensure durability and efficiency in marine vessels, making them the preferred choice for shipbuilders and marine engineers.

Filium’s Role in the Indian Market

Filium is not only a leading supplier of spiral bevel gears but also a key player in India's engineering solutions market. As industries in India rapidly evolve, the need for high-quality mechanical components such as spiral bevel gears continues to rise. Design engineers looking to buy spiral bevel gears in India can rely on Filium for durable, high-performance gears that meet global standards.

Filium’s ability to supply both standard and custom spiral bevel gears makes it the ideal partner for projects in diverse industries. The company’s extensive range of products is backed by expert engineering support, ensuring that each gear is designed and manufactured to exact specifications.

Conclusion: Why Filium?

For design engineers seeking reliable, high-quality spiral bevel gears, Filium offers a comprehensive solution. Whether the application is in automotive differentials, aerospace control systems, or industrial robotics, Filium’s spiral bevel gears provide the precision, durability, and flexibility required for high-performance projects. By choosing Filium, engineers can rest assured that they are getting gears that meet the most demanding industrial standards.

If you're looking to buy spiral bevel gears in India, Filium is the partner you need for advanced mechanical solutions. With an extensive product range, custom engineering support, and a reputation for excellence, Filium is at the forefront of gear manufacturing in India.