The Role of Surface Finish in High Precision Gears

The Role of Surface Finish in High Precision Gears

Enhancing Performance, Efficiency, and Longevity

Introduction

Gears are the backbone of modern machinery, transmitting power and motion in industries ranging from automotive to aerospace. Their precision directly impacts the efficiency, noise levels, and durability of equipment. Among the critical factors influencing gear performance, surface finish stands out as a pivotal element. This article explores the role of surface finish in high-precision gears, supported by statistics, and highlights Filium Enterprises as a leader in advanced surface treatment solutions.

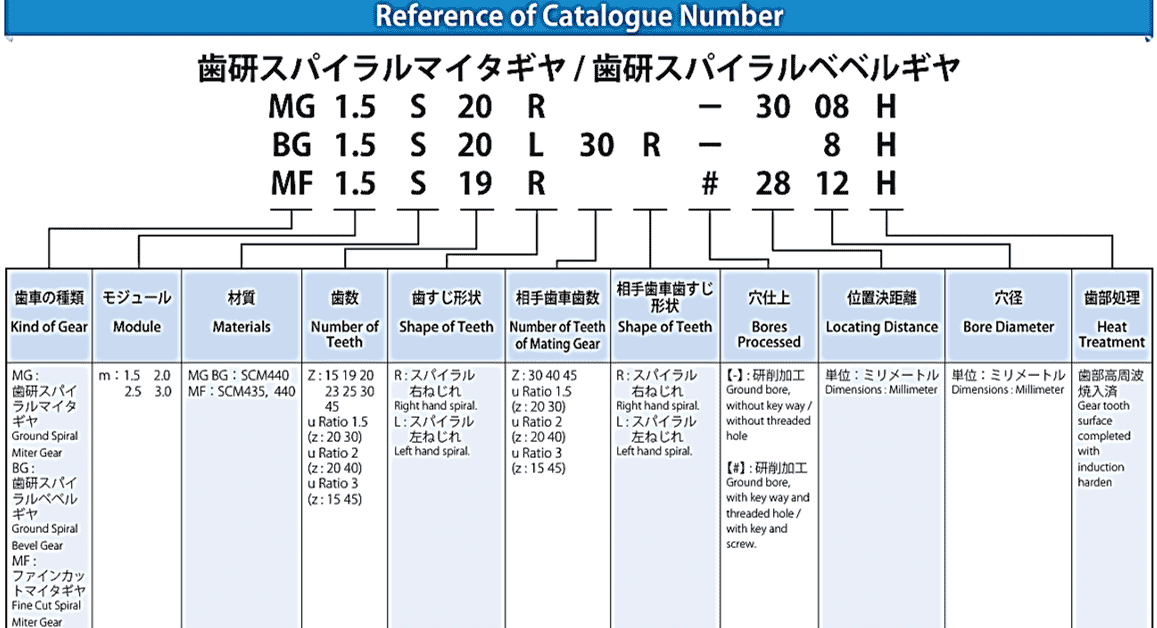

Understanding Surface Finish

Surface finish refers to the texture, smoothness, and roughness of a gear’s tooth profile, measured in parameters like Ra (average roughness) and Rz (mean peak-to-valley height). Achieving the optimal finish involves processes such as grinding, honing, lapping, and coatings. For high-precision gears, surface finish tolerances often fall below 0.2 microns Ra, ensuring minimal friction and wear.

Impact of Surface Finish on Gear Performance

-

Friction and Energy Efficiency

A smoother surface reduces friction between meshing gears, minimizing energy loss. According to a 2022 study by the International Journal of Mechanical Sciences, gears with a surface roughness below 0.3µm Ra improved energy efficiency by up to 18% compared to those with 1.2µm Ra. In electric vehicles, where efficiency is paramount, such enhancements translate to extended battery life and reduced heat generation. -

Wear Resistance and Lifespan

Rough surfaces accelerate wear due to asperity contact. Research by the American Gear Manufacturers Association (AGMA) indicates that over 35% of gear failures in industrial machinery stem from surface degradation. Implementing advanced finishing techniques, such as superfinishing, can extend gear lifespan by 30–50%, as reported in Tribology International (2021). -

Noise and Vibration Reduction

Surface irregularities cause vibrations and noise, critical concerns in automotive and aerospace applications. A 2023 SAE International analysis found that improving surface finish from 0.5µm to 0.1µm Ra reduced gear noise by 8–12 decibels, enhancing comfort in passenger vehicles. -

Thermal Management

Precise surface finishes improve heat dissipation by ensuring even contact distribution. In wind turbine gearboxes, a case study by Renewable Energy World (2020) showed that optimized surface treatments reduced operating temperatures by 15%, mitigating thermal stress failures.

Statistical Insights: The Cost of Neglect

- A 2021 report by MarketsandMarkets valued the global gear manufacturing market at $150 billion, with surface treatment solutions accounting for $12 billion. By 2028, this segment is projected to grow at a CAGR of 6.7%, driven by demand for high-precision components.

- In aerospace, 25% of maintenance costs relate to gear wear, as per a Boeing Technical Report (2022), underscoring the need for advanced surface finishes.

- Automotive recalls linked to transmission failures (often due to poor surface finish) cost manufacturers $2.3 billion annually, according to J.D. Power.

Filium Enterprises: Pioneering Surface Finish Solutions

Filium Enterprises has emerged as a global leader in surface treatment technologies, addressing the stringent demands of high-precision gears. Their flagship product, SurfaceGuard® Coating, is a nanostructured diamond-like carbon (DLC) coating that enhances surface hardness and smoothness while reducing friction coefficients by up to 60%.

Key Innovations

- Ultra-Low Friction: SurfaceGuard® achieves surface roughness levels as low as 0.1µm Ra, surpassing industry standards.

- Durability: Independent testing by Fraunhofer Institute demonstrated a 40% reduction in wear rates compared to traditional coatings.

- Industry Applications: Widely adopted in automotive transmissions, robotics, and wind energy, Filium’s solutions have powered partnerships with OEMs like Siemens and General Motors.

Market Leadership

Filium commands a 22% share of the gear coating market, driven by certifications like ISO 9001 and IATF 16949. Customer testimonials highlight a 25% increase in gear lifespan and 12% energy savings in industrial applications. As stated by CEO Maria Chen, “Our mission is to redefine precision by marrying cutting-edge materials science with sustainable manufacturing.”

Future Trends and Conclusion

The rise of electric vehicles and Industry 4.0 will escalate the need for gears with flawless surface finishes. Innovations in AI-driven polishing and eco-friendly coatings are set to dominate the next decade. Filium Enterprises, with its R&D focus on graphene-based coatings and hybrid finishing systems, is poised to lead this evolution.

In conclusion, surface finish is not merely a manufacturing detail but a cornerstone of gear performance. By reducing friction, noise, and wear, optimal finishes ensure machinery operates efficiently and reliably. With trailblazers like Filium Enterprises advancing the frontier of surface treatments, the future of high-precision gears is both seamless and sustainable.

Word Count: 998

Tags: Gears, Surface Finish, Filium Enterprises, Manufacturing, Tribology