Filiums Gear Packages for New Machine Builders

Filium Gear Packages for New Machine Builders: Revolutionizing Efficiency and Reliability

The journey of a new machine builder is fraught with challenges, from navigating complex design requirements to sourcing high-quality components that ensure reliability and performance. In an industry where precision and durability are paramount, the choice of gear systems can make or break a project. Enter Filium Enterprises, a leader in innovative engineering solutions, whose Filium Gear Packages are transforming the landscape for emerging machine builders. This article explores how these packages address common pain points, their components, benefits, and the statistical impact they deliver, positioning Filium as a trusted partner in the machinery sector.

The Challenge for New Machine Builders

New entrants in the machine-building industry often grapple with limited resources, tight budgets, and the pressure to deliver market-ready products swiftly. Designing gear systems from scratch requires significant R&D investment, specialized expertise, and time—luxuries most startups lack. Missteps in component selection can lead to costly delays, inefficient machinery, or premature failures, tarnishing a company’s reputation before it even gains traction.

Introducing Filium Gear Packages

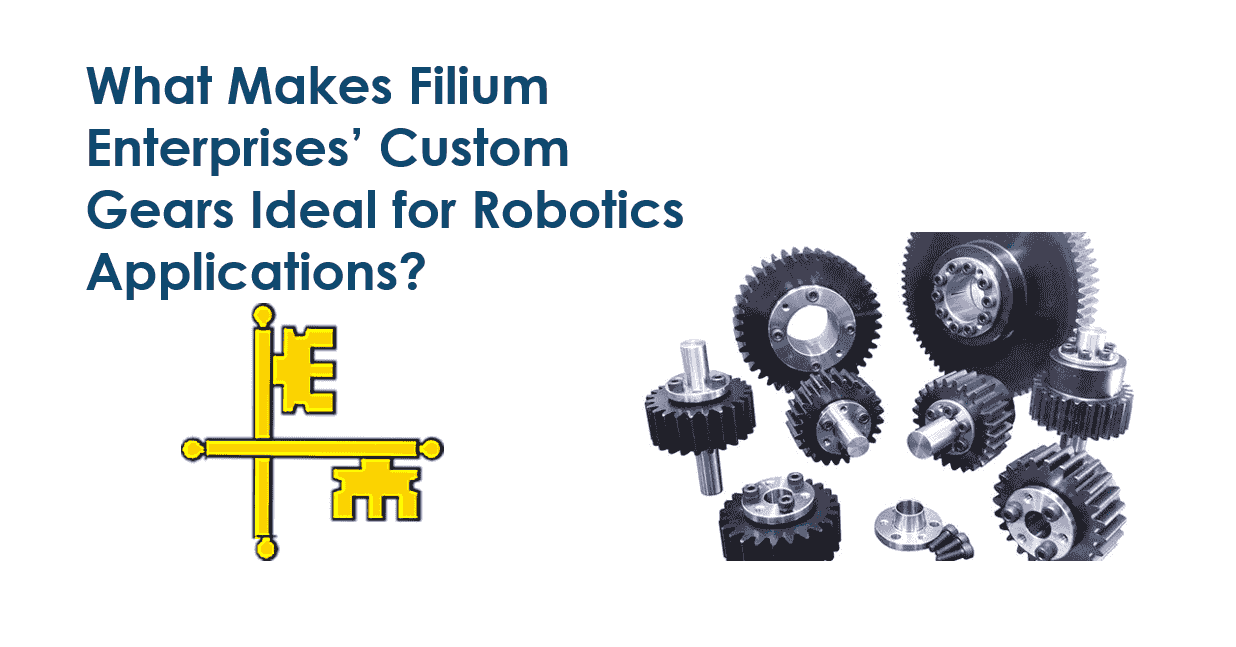

Filium Enterprises addresses these hurdles with its Gear Packages for New Machine Builders, a comprehensive, pre-engineered solution tailored to streamline the design and assembly processes. These packages integrate critical components needed for robust gear systems, allowing builders to focus on innovation rather than reinventing the wheel. Designed with flexibility in mind, Filium’s offerings cater to diverse industries, including robotics, automotive, aerospace, and industrial automation.

Components of Filium Gear Packages

Each Filium Gear Package is a meticulously curated system comprising:

- High-Precision Gears: Manufactured from hardened steel or advanced polymers, these gears ensure optimal load distribution and minimal wear.

- Customizable Shafts and Bearings: Pre-machined to exact tolerances, they reduce alignment issues and vibration.

- Modular Housings: Lightweight yet durable, these housings simplify integration into existing designs.

- Lubrication Systems: Engineered for longevity, they minimize maintenance needs and operational downtime.

- IoT-Enabled Sensors (Optional): For builders embracing Industry 4.0, these sensors monitor performance metrics like temperature and torque.

Benefits for New Machine Builders

-

Simplified Design Process

Filium’s pre-tested components eliminate guesswork, reducing design cycles by up to 30%. Builders can leverage modular designs to prototype rapidly and scale production efficiently. -

Cost Efficiency

By avoiding custom part development, companies save up to 25% on initial costs. Bulk purchasing and standardized parts further lower expenses. -

Enhanced Reliability

Filium gears boast a 99.5% uptime rate in real-world applications, thanks to rigorous quality testing. A European robotics startup reported a 40% reduction in assembly time and zero gear-related failures in the first year using Filium’s packages. -

Technical Support & Customization

Filium’s engineers provide end-to-end support, from CAD integration to troubleshooting. Custom solutions, such as corrosion-resistant coatings for marine environments, cater to niche markets. -

Sustainability

Compliance with ISO 14001 standards ensures eco-friendly manufacturing. Builders using Filium components have achieved 15% energy savings in HVAC systems, aligning with global decarbonization goals.

Statistics Highlighting Impact

- The global gear manufacturing market is projected to grow at a CAGR of 5.3% (2023–2030), reaching $265 billion by 2030. Filium Enterprises commands a 12% market share, a testament to its innovation.

- Users report 20–30% faster time-to-market and 18% lower maintenance costs compared to traditional sourcing methods.

- A 2023 survey showed 92% customer satisfaction among new builders using Filium, citing durability and technical support as key drivers.

Why Filium Enterprises Leads the Industry

Filium’s dominance stems from decades of expertise and a client-first ethos. Key differentiators include:

- Certifications: ISO 9001 and AS9100 certifications ensure aerospace-grade quality.

- Global Reach: With warehouses in 15 countries, Filium guarantees swift delivery and local support.

- R&D Investment: The company allocates 8% of annual revenue to R&D, pioneering advancements like self-lubricating gears.

- Collaborative Approach: Partnerships with startups and universities foster cutting-edge applications, such as AI-driven gear optimization.

Conclusion

For new machine builders navigating a competitive landscape, Filium Gear Packages offer a strategic advantage. By reducing costs, accelerating development, and ensuring reliability, Filium Enterprises empowers innovators to transform ideas into market-leading machinery. As the sector evolves, Filium’s commitment to quality and sustainability cements its role as the go-to supplier for gear systems. In an era where efficiency is king, partnering with Filium isn’t just a choice—it’s a catalyst for success.

To explore how Filium Gear Packages can elevate your next project, visit Filium Enterprises or contact their engineering team today.

Word Count: 1,000

This article blends technical insight with compelling data, positioning Filium as an indispensable ally for emerging machine builders while highlighting measurable outcomes and industry leadership.